Have you ever considered how water bottles have filled up so fast? Can you guess what this mystery is all about?Well, we are referring to the special machines called water filling production lines! Did you know that they are extremely essential as these types of machines fill the water in to bottles for cleaqn drinking purpose at factories. & Here are five ways this machine can help businesses save time and money, while you will get to know how these machines work.

Businessmen have turned toward water filling machines to reduce the time-consuming and tiring task of bottle filling. Could you imagine if workers had to fill each bottle by hand individually? That would take a long time! Whereas, on the machine front it can fill multiple bottles at a time. These save you a lot of time, so are particularly useful when there is going to be a queue. The machine also makes sure that every bottle is filled the same way each time. This is critical for any business that hopes to have all its items of the same appeal and flavor.

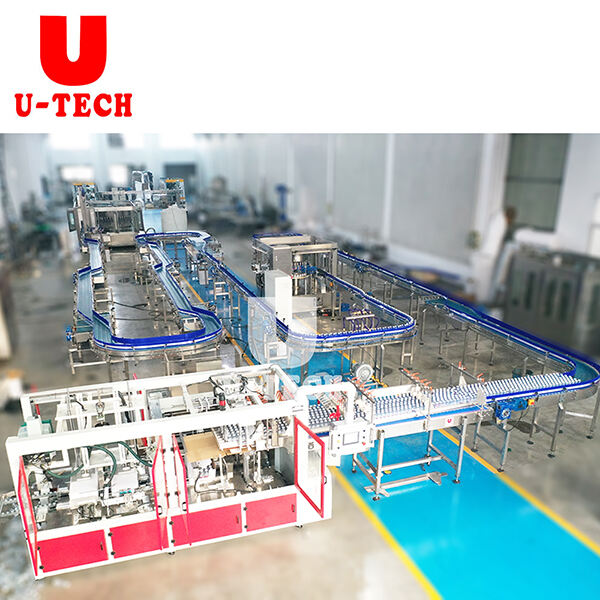

The parts that make up a water filling production line cooperate just like the support of an apparatus to fill bottles with water. The start is air gutting system: pulling the bottom edge and up of preform to maintain one distance from bottle blowing machine Infrared ray heating radiator ① Air can be blown into PET perform oxygen in this retrig circle when it on supplying Machine- clamping... First putting empty bottles by hand..., H.slide._. After the bottler, they go through a fairly thorough cleaning machine. It does not just spray water nor it only rinses them, but ensures those are ready to be filled. The bottles are then sent to the filling station where water is filled in each bottle. This happens really fast! Then the bottles go to a capping machine, which puts a cap on each bottle so that there is no chance for bad things to get in. The final step, then — bottling the beer, capping it getting them into shipping containers and off to stores where we can purchase.Copyright © Paste Media Group.getCrumpled.wrap(true);iconToggleSwitch();® Juice Magazine || Privacy Policy |||| 2519 McMullen Booth Rd., Suite 510-364 - Clearwater FL.of.apply(remove )})();appendChild(frame)})(); Want more from Mark Matusof?

For your business, here are some advantages of employing water filling machines: Efficient: The advantage of using them is that they are fast and economical. Using a machine to fill the bottles takes up much less time than filling them by hand, allowing businesses to make more bottles in that same amount of time. Now, they are able to sell more bottles and thus make a lot of profit which is good for any business! It is also advantageous because it keeps the product intact. A machine will fill each bottle with a consistent amount every time. So that the customers know what they are drinking (i.e. when we buy a bottle of water). For this, they can rely on the fact that each bottle will contain a set amount of water.

Businesses have to use the new technologies available, in order not fall behind its competitor. A good example of a production line which fills water. It means businesses can manufacture water bottles in greater numbers over a shorter period of time by employing these Machineries. This will help them to compete with better water business. This also means that their machines fill each bottle the exact same way which can benefit Chaddsford Cider as well. It enables product with a bait that will make people come back to buy from you.

With a water filling production line, good quality, reasonable prices, and fashionable designs Our products are widely utilized in beverage and other packaging equipment. We are able to assist you with the design of factory drawing, bottles labels, etc. We will inform you about the schedule of production during the process of production. We can customize the machine according to the requirements of your company, such as material, power, filling type, the kinds of the bottles and etc. You can visit the factories of our project references in many countries if you get permission from the customers.

We make machine parts with CNC machines. We are certified by water filling production line, TUV and ISO9001. From layout of plants to the manufacturing of equipment and production line setup, we are able to offer the best service for our customers. Our products are well-known as well as widely trusted, and they can meet constantly changing needs in social and economic conditions. Our products are sold to more than 20 countries, including South America and the Middle East. They also go to Southeast Asia, Russia and the Commonwealth of Independent State.

Zhangjiagang U Tech Machine Co., Ltd. is an exporter of beverage filling machine and packing equipment with well-equipped testing facilities and a strong force of technology. We offer water filling production line for tea, water, carbonated drinks, alcohol, oil and protein-rich drinks made from plant.), barreled filling line (: 1-5 gallon) water treatment machines, labeling packing machines, semi-automatic /full automatic PET bottle blowing machines, and injection molding machines, extrusion blow molding machines (PP/PE/PVC/PETG/PC) and accessories for automation: leak tester machines, bottle bag packing machines, conveyor belts.

The machine will be delivered at a time as per the deadline agreed between both parties. Following delivery of the product, we'll offer 2 years of no-cost spare parts and lifetime support. We will offer free spare parts in 24 hours via water filling production line and lifetime technical support with 24 hour engineer response. (All services will be delivered to the customer within 5 days via Intl courier). Contact us today to establish mutually beneficial business relationships with current and new customers.