Milk is a tasty and healthy drink intake of which Maqy like to have it every day(Most of them). Most of the people drink cow's milk only but other types of milk such as goat and sheep are also liked by few. Even camel milk is catching on! Fresh milk collected from the animals is critically needed to be bottled as soon possible. That way it stays fresh and clean...and delicious, safe to drink. There are specialized machines, called milk bottling machine to efficiently perform this pivotal task.

As the name suggests, these machines have been developed for filling of milk bottles and therefore can be termed as Milk Bottling Machines. This is an extremely user friendly way to protect and contain a volume of milk that needs to be bottled up; making it perfect for commercial businesses. Some of these machines can fill up several bottles at the same time, so you will be done with this activity in no-time. In different shapes and size to milk actually, be bottling in what psi have of containers. There are those built for small scale farms, and there are also others constructed with large factories in mind.

The smart technology used by milk bottling machines is there to insure that the best quality of miIk reaches you. That also means the machinery like machines are tortuously crafted, so as to nothing appear taken separately will have a separate personal existence. They are constructed to clean with the utmost ease and cleaning mail goals.keeping milk safe enough that all can drink.

The process of milk bottling should be done in a fastidious and quick way to avoid any flaw. Machines are equipped with sensors that know exactly when the milk starts ane stops coming and also when bottle is full. This also helps ensure that each bottle is full exactly to a certain level, in order to prevent milk from running over. This technology allows the work area to keep clean and does not waste any.

Because, milk bottling machines are made according to the category of a business. All organizations are different, and so may possibly exactly how cans they have got. That way the machines can be modified to fit around whatever size and shape of milk container a business is using. There are machines that fill glass bottles and there are other for plastic ones.

These devices additionally purpose to generate as little waste at the time of bottling These are constructed with re-installable accessories, so if some part of machine undergoes a breakdown that particular portion is replaced instead of being thrown away. They are also engineered bottle to waste less milk and save on cost.

Milk bottles go through the milk bottling machine to ensure that they are free of any pathogens. So, they make an excellent choice for not having to worry over whether the milk is safe and suitable for everyone in terms of being clean. An enormously important factor in this because no one wants to drink milk that is not healthy.

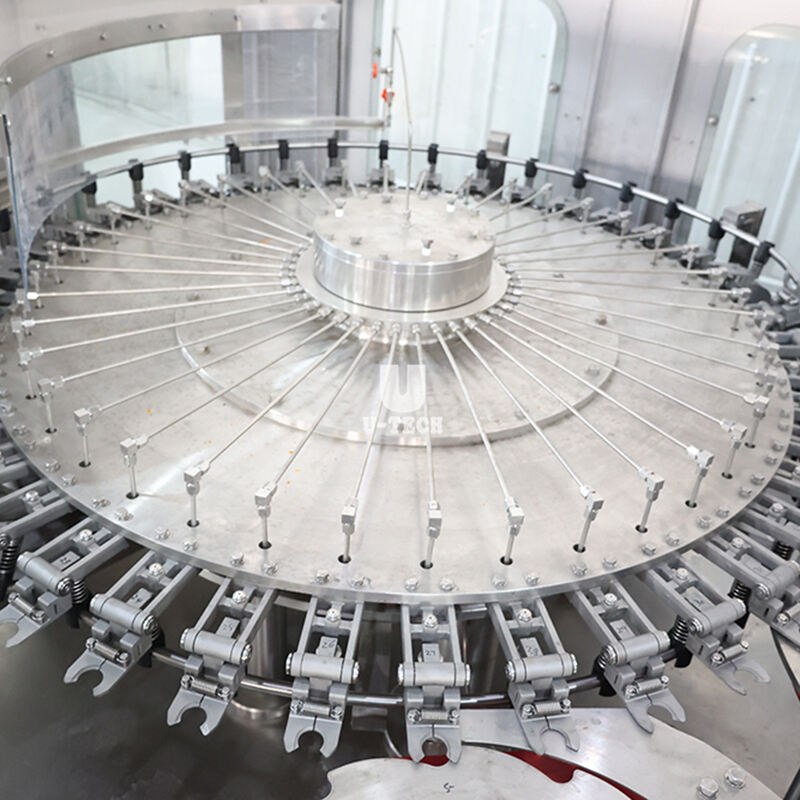

Our products are extensively used for packaging beverages and other equipment due to their broad selection, quality, affordable prices and attractive designs. We can design bottles, labels or milk bottling equipment. We will keep you informed of the schedule for production throughout the process of production. We will customize the machine in accordance with your requirements, materials power, filling type and the types of bottles and the like. You can visit the manufacturing facilities of our project references across the world if you have permission from customers.

We will provide your machine in accordance with the scheduled date. Once we have delivered the product, we'll provide two years of free spare parts and lifetime support. We will supply free spare parts for 24 hours via international professional express and lifetime technical support, with 24 hour engineer response. (All services are delivered to the customer in five days using Intl courier). We welcome new and old customers from all aspects of life to get in touch with us to discuss future business relations and the milk bottling equipment!

Zhangjiagang U Tech Machine Co., Ltd. is an exporter of beverage filling machine and packing equipment with well-equipped testing facilities and a strong force of technology. We offer milk bottling equipment for tea, water, carbonated drinks, alcohol, oil and protein-rich drinks made from plant.), barreled filling line (: 1-5 gallon) water treatment machines, labeling packing machines, semi-automatic /full automatic PET bottle blowing machines, and injection molding machines, extrusion blow molding machines (PP/PE/PVC/PETG/PC) and accessories for automation: leak tester machines, bottle bag packing machines, conveyor belts.

We make machine parts with CNC machines. We are accredited by CE, milk bottling equipment and ISO9001. We provide the highest quality of services for our customers, starting including plant layout production equipment, layout and line configuration to operator training as well as the most efficient after-sales service. Our products are widely recognized and trusted by consumers and can meet continuously changing requirements in social and economic conditions. Our products are currently exported to more than 20 countries including South America and the Middle East. They also export to Southeast Asia, Russia and the Commonwealth of Independent States.