A: A wine bottle filling machine is a sort of specialized machinery helping wineries quickly and easily fill up bottles with their wines. Although there are many advantages when it comes to using these machines over manual filling the bottles. To begin with, they are a lot faster and more automated than doing this manually so wineries can fill many bottles in short order. This is a big deal for them, because it helps them to meet the demand of their wines. Along the second line, and these machines will assist in prevention of spills and waste which can occur while filling bottles by hand. No one likes to waste wine! Third, ensuring that every bottle has the same volume of wine is very important to customers who want to know they are consistently receiving uniform product quality. Fourth, the use of these machines helps maintain the wine free from bacteria which are not any good and will spoil the taste as well as health.

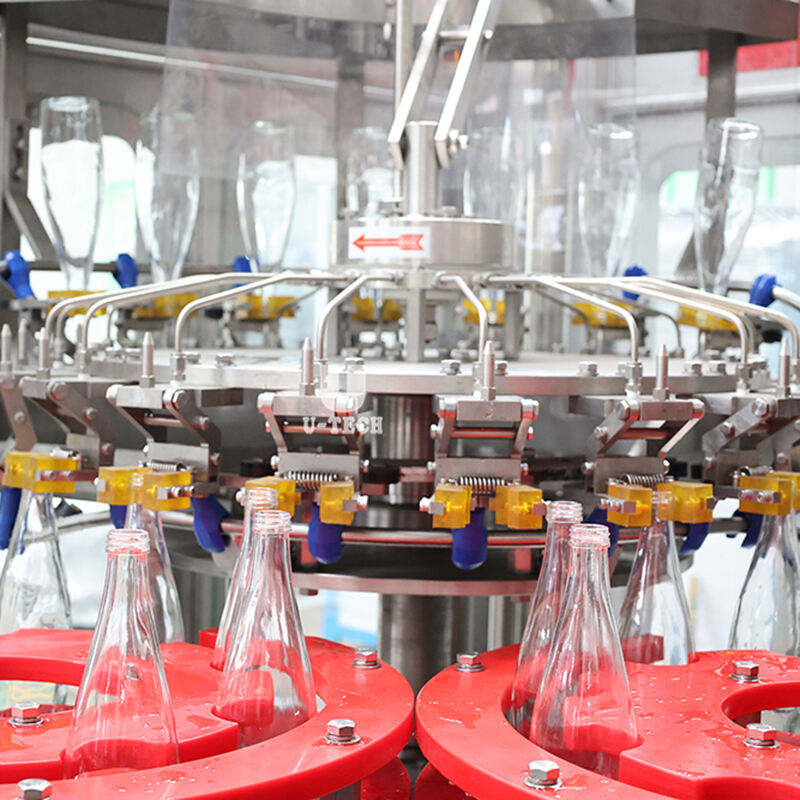

There are various components that work in coordination to fill the bottles by wine bottle filling machines. A part of these elements are a transport line, filling spout and control board. We will start with the empty bottles which are put on a conveyor belt and from there they move through to where the filling occurs. To refill the bottles with wine, another part of the nozzle is producing sequence. This is super critical because it pours the perfect amount of wine into future bottles. Third, the machine checks to verify that after filing bottle is filled up with required level. This step is particularly important because filling the bottle incorrectly can deteriorate both taste and quality. Next, the filled and sealed bottles are taken to another area of this factory where they will be labled (read, applied with a sticker) then packed for sale. All of this is done very quickly and efficiently, which makes it a popular choice for many wineries.

In a winery, wine filling machines are very essential. They make the fill time quick and simple which, in a commercial winery translates into speed of production...which equates to money. It is especially useful now in the busy time when wineries have to produce a great amount of wine for its clients. On top of this, these machines produce better quality wine by delivering them to the exact fill height. This consistency is key for upholding the wine's quality from bottle to bottle. Additionally, the wine filling machine also reduces waste and spills which not only saves money for wineries but is fantastic for the environment as well. Not only is the use of these winery machinery items good for the environment, but a lot of customers also like it that way.

Wine filling machinesAre the Future of Wine FillingMachines Here to Stay? As technology improves, these machines will continue to get smarter and more efficient. Unfortunately, this just means they can fill wine bottles even faster and more accurately regardless of how fast or inaccurately they are being filled now. Not to mention, as more wineries try to become environmentally efficient these machines will be built with energy saving and waste production in mind. A positive trend as it means the wine industry is acknowledging its impact on our planet and doing something to lessen that.

It is simple to determine how wine bottle filling machines increase the quality of a bottled wine and here are some essential features associated with this machine, which explain better.

Wine bottle filling machines make wine better -wine needs help. To start, they make sure that the wine is filled to exactly where it needs to be which as you will know if very important for the how the final product tastes and smells. A bottle that isn't filled correctly can affect the way a wine tastes and smells, which is not what any winemaker wants. The second reason is that these machines help to prevent contamination as human-to-hand transfer has been removed thereby reducing the risk of contamination. Because only humans fill bottles by hand, mistakes will be made - but machines can always do the job more consistently. B) Wine filling machines ensure the quality of your wine from one bottle to another and that is important for making sure customers get what they expect, every time. In the end, they also reduce waste and spills - a winery's spillage is both damage to your wine as well as money out of the pockets.

We make machine parts with CNC machines. We are accredited by CE, wine bottle filling machine and ISO9001. We provide the highest quality of services for our customers, starting including plant layout production equipment, layout and line configuration to operator training as well as the most efficient after-sales service. Our products are widely recognized and trusted by consumers and can meet continuously changing requirements in social and economic conditions. Our products are currently exported to more than 20 countries including South America and the Middle East. They also export to Southeast Asia, Russia and the Commonwealth of Independent States.

Zhangjiagang U Tech Machine Co., Ltd., a beverage filling machine maker and packaging firm with a talented technical team and well-equipped test facilities. We supply liquid filling machines for tea, water, carbonated beverages, alcohol, oil and plant protein drinks.), wine bottle filling machine (: 1-5 gallon) water treatment machines, labeling packing machines, semi-automatic /full automatic PET bottle blowing machines, and injection molding machines, extrusion blow molding machines (PP/PE/PVC/PETG/PC) and accessories for automation: leak tester machines, bottle bag packing machines, conveyor belts.

With a variety of products with good quality, competitive pricing and trendy designs our products are extensively employed in beverage and other packaging equipment. We can design bottles, labels, factory drawings, etc. When the machine is in production we will make changes to the production schedule for you on the appropriate date. We will customise the machine to meet your specifications such as material, power and filling type, bottles, and so on. We have reference projects in a variety of countries and we can show you their facilities if we have the wine bottle filling machine.

The machine will be delivered at a time as per the deadline agreed between both parties. Following delivery of the product, we'll offer 2 years of no-cost spare parts and lifetime support. We will offer free spare parts in 24 hours via wine bottle filling machine and lifetime technical support with 24 hour engineer response. (All services will be delivered to the customer within 5 days via Intl courier). Contact us today to establish mutually beneficial business relationships with current and new customers.