If you like ice-cold drinks, chances are that beer rings a bell. Beer is a beverage since ancient times, the demand side of packaging business. It has widespread popularity because it comes in many flavors and kinds. The FourRing system: Some people just prefer beer from a can or others swear by the bottle. When beer is coming out of a bottle, that taste and drinking feeling is something more special than the hole experience when we drink form can. But the problem is that not all breweries, as in smaller companies cannot afford machines to put their beer into bottles.

Small breweries only make small amount of beer, unlike big companies that produce a lot. It is necessary because, after all these are small breweries who definitely can not afford to buy a machine which expenses too much and they also require bottling machines for brewing faster. Small breweries are mostly in small towns, where usually people like stronger and heavier tastes of beer. Very often, have a lot of trouble in getting hands on equipment that can they afford better and which will not end up sitting idle.

Thankfully, there are plenty of solid packaging choices for small breweries out there. So basically, these are not only inexpensive options since they do not spend too a lot of money but also easy to be managed and used. Clear instructions for any given device (a must-have feature since small breweries do not have the luxury to experiment as much). Instructions should be in laymans terms and not complex terminology making it easy for everyone to understand how operate the machines properly.

For all the beer-lovers out there - technology is making things better for everyone, even you. This has led to a lot of businesses that make things beginning using machines and technology in order to help them work even faster. That is automation and it has made world bottle machines faster, improve anyway. This new technology has changed the brewing world, giving many of these small breweries a fighting chance.

Ultimately small breweries will need to vet their bottling machine options carefully. Some factors make it a good one, the likes of which should use with ease, are quick to repair in case something goes wrong and seals bottles fast. There are semi-automatic, automatic and manually operated machines that small breweries can afford for bottling of beer. Every one of these choices can be advantageous for those smaller breweries to bottle their beer correctly.

How precision machinery is changing the way small breweries compete The first is that they guarantee the quality of a beer every time you open one. It is this consistency that drives consumer satisfaction. Two, to help minimize waste: every keg-to-glass rate means less beer being tipped down the drain and more in front of your customer. Secondly, Precision machines are usually used to increase production efficiency because they allow for more beer output with fewer people working (esit all costs.).

They have created unique types of facilities such as beer taps, casks and packages to help facilitate the perfect way for their product is poured. Users can also create their beer taps to be personalized to align with the user's unique style and taste. Bonobos defines how they just customize with pride over tailoring, which is more appealing than any one KPI because a memorable customer experience.

The machine will be delivered on time to the deadline agreed between both parties. We will offer 2 years free spare parts, and beer bottling equipment once the product is delivered. We'll provide spare parts in 24 hours via international express professional and all-year technical support with 24 hour engineer response. (All services are delivered to customers within 5 days via Intl courier). We are happy to welcome both old and new customers from all types of industries to reach us for future business relationships and shared success!

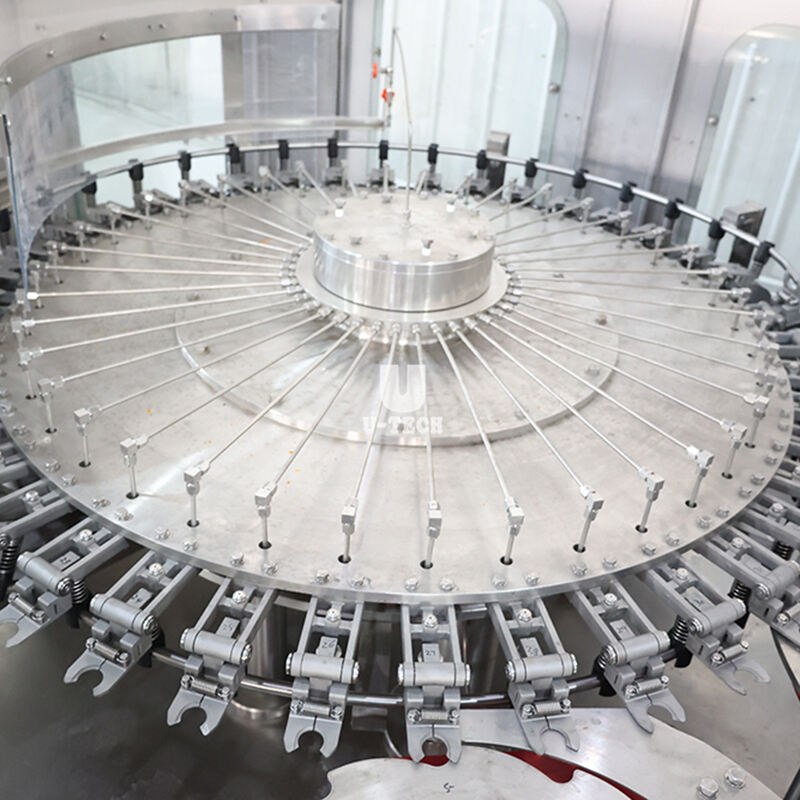

Zhangjiagang U Tech Machine Co., Ltd., a manufacturer of beverage filling equipment and beer bottling equipment, has a strong technical team and well-equipped test facilities. Our products include liquid filling machines (water or fruit juice/tea carbonated drink, oil alcohol, plant protein drink, etc), barreled filling line (: 1-5 gallon) water treatment machines, labeling packing machines, semi-automatic /full automatic PET bottle blowing machines, and injection molding machines, extrusion blow molding machines (PP/PE/PVC/PETG/PC) and accessories for automation: leak tester machines, bottle bag packing machines, conveyor belts.

With a wide range, good quality, reasonable costs and attractive designs Our products are widely utilized in beer bottling equipment and other packing equipment. We design bottles, labels as well as factory drawings. We will keep you updated of the timetable for production during the process of production. We will customise the machine to your specific requirements such as material, power and type of filling bottle styles, etc. You can visit the factories of our projects as reference across the globe if you are granted permission by the customers.

We manufacture machine parts using a CNC machine. We are accredited by CE TUV, CE, and ISO9001. We are able to provide beer bottling equipment for our clients, including plant layout manufacturing equipment and production line configuration to operator training and top after-sales services. Our products are well-known and trusted by consumers and are able to meet ever-changing demands in the social and economic spheres. Our products are now exported to more than 20 countries and regions which include South America, Middle East, Southeast Asia, Russia as well as the Commonwealth of the Independent States, Western Asia and South Africa.