Wondering how machines support the making of products like shampoo and juice? At present let us take you all in on details of fuel liquids via unique machine known as the U Tech servo liquid filling machine. At first, this liquid filling machine might look surprising. It really makes eye-notes for people who are making these. In this article we will delve deeper to understand what is CNC machine and its usage for manufacturers.

In some cases, filling of liquids is a real headache for manufacturers (eg shampoos juices or hand sanitizers). To do this, they have to be very precise while measuring the liquid. They must also consider available containers. This is often a tedious and time-consuming procedure. The servo liquid filling machine is quite an assisting element at.

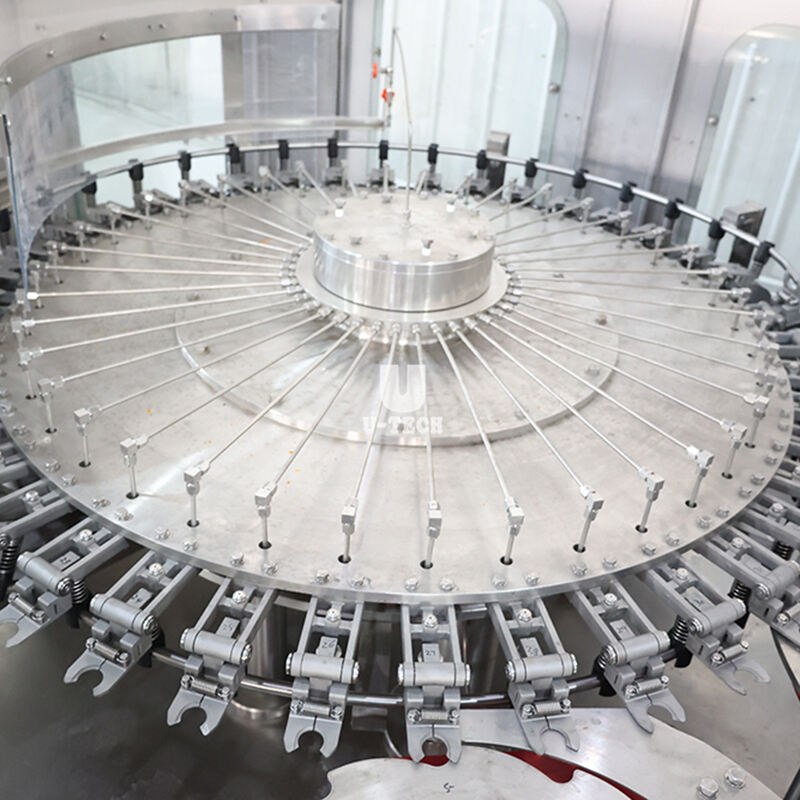

This U Tech servo liquid filling machine is why servo motors are very different. The servo liquid filling machine ensure the machine does not vibrate or bounce around. A smooth mechanical operation is crucial. The bottle filling machine will eliminate spills or any issues during the fill-up. Those smooth movements also help the machine keeping accurate when it fills many bottles in a row. This ensures each bottle gets filled just right.

Hand filling liquids was very time consuming and could lead to mistakes often. It pains me to even think about doing this task for hundreds and thousands of bottles manually. That would be busywork and lead to bigger troubles. However now machines do job much quicker and with a higher degree of precision provided by servo technology.

With these machines, the filling process is faster. There are less errors made using the U Tech servo liquid filling machine. Without having to be manually adjusted they are able to place the precise volume of liquid in each container. This water filling machine ensures less waste and saves a lot of time and money. Faster manufacturing occurs as no time is wasted in redoing products.

This enables manufacturers to make more items faster. In that way, they will fill requirements of these customers and can grow their businesses to grind out a living. In addition the machines ensure that bottles are filled precisely to reduce waste. Hassle-free! We fill every bottle to maximum capacity and it helps both you as well as environment!

For instance, specific liquids have unique characteristics that require them to be filled at various speeds or temperatures. Furthermore, distinct bottles may have different shapes and sizes which can affect the way they are filled. U Tech servo liquid filling machine systems feature adjustable settings in all these areas, which makes the water bottle filling machine an excellent choice for a lot of manufacturers.

We create machine parts with a CNC machine. We hold CE TUV, CE, Servo liquid filling machine certification. From plant layout to production equipment manufacture and line set-up, we can provide the highest level of service to our clients. Our products are well-known and trusted by users and can meet continuously changing social and economic needs. Our products are now exported to more than 20 countries and regions that include South America, Middle East, Southeast Asia, Russia, the Commonwealth of the Independent States, Western Asia and South Africa.

With a variety of products with good quality, Servo liquid filling machine, and fashionable designs our products are extensively used in beverage as well as other packing equipment. We design bottles, labels, factory drawings, etc. We will keep you aware of the production schedule during the production process. We will design the machine according to your requirements, materials power, filling types, the kinds of the bottles and so on. You can visit the factories of our project references in many countries if you are granted permission by the customers.

Zhangjiagang U Tech Machine Co., Ltd. is a supplier of beverage filling machines and packaging with well-equipped testing facilities and Servo liquid filling machine. We provide liquid filling equipment for tea, water, carbonated drinks, alcohol, oil and protein-rich drinks made from plant.), barreled filling line (: 1-5 gallon) water treatment machines, labeling packing machines, semi-automatic /full automatic PET bottle blowing machines, and injection molding machines, extrusion blow molding machines (PP/PE/PVC/PETG/PC) and accessories for automation: leak tester machines, bottle bag packing machines, conveyor belts.

We will deliver the machine on time to the date set by both parties. Following the delivery of the item, we will give Servo liquid filling machine of complimentary spare parts and lifetime support. We will provide free spare parts in time within 24 hours through international professional express, and offer lifetime technical support for the machine, 24/7 for response from engineers (all services part 5days in the customer's hands by Intl' Courier). We welcome new and old customers from all types of industries to reach us for future business partnerships and the mutual benefit!