In this text we are going to see something more focusing on bottling but now in capping machines. These are some really cool and important machines! If you need something to slam caps fast on bottles. If you own a business where there is a need to cap many bottles, then investing in a bottling capping machine might be all the help that you require to ease and speed work. You imagine the many bottles you have to cap and realize how long it would take by hand as opposed to running your new capping machine.

If you make many bottles, it may be really time consuming and exhausting work to put caps on those by hands. That is why we use bottling capping machines here! Did the machine able to put each down faster than having a person do one by eine This is how your business works smarter and get far more accomplished in significantly less time. The amount of time and energy that you are able to save instead of doing it all by hand!

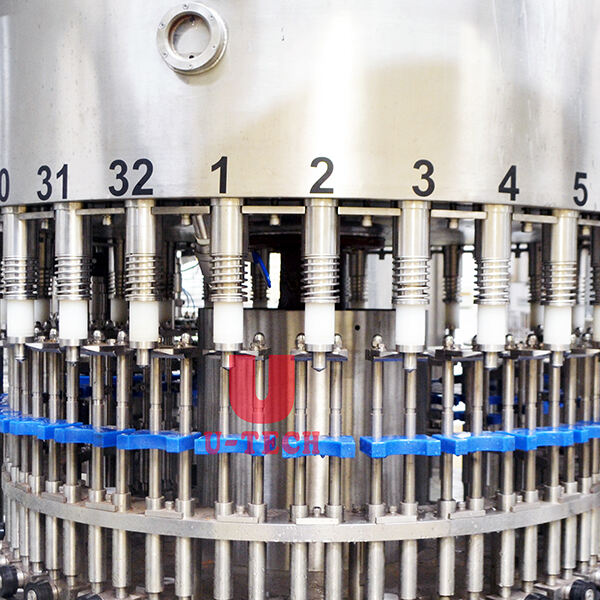

Innovation is all about coming up that new and improved method of doing something, which brings you to the world of Innovative capping machines! Such highly sophisticated machines assist in bottling by automatically applying caps on top of bottles through strategic use of technology. This way you do not have to get out there and try, which is slow as well as frustrating at times. No, the machine makes all of that go much faster and smoother for you to do other things your business sorely needs.

The best type overall for your business is a state-of-the-art bottling capping machine. This tool integrate the most advanced and intelligent technology that will be useful for your industry to work smoothly. With one of the bottle making machines you can streamline your bottling process and get more done in less time. It means you can make your customers more satisfied by delivering them product in less time.

Advanced capping technology — provides you with latest and most reliable class of machines Which means that every one of your bottles will have the cap on, guaranteed and you can visually verify it. This ensures that each bottle is in the best possible form and ready to go, at all times so your customers never receive any defective goods. This not only enhances the quality of your products but also makes you build a well image in the market.

A fast and powerful capping machine If you sell lots of bottles, right away these machines will help you to cap a lot of bottlenecks quickly and efficiently. As a result, you can manufacture more things than ever! Additionally, they are designed to be high performance and ultra-reliable so you do not have downtime during peak hours. That will allow for you to work on the business instead of working in it fixing machines.

Zhangjiagang U Tech Machine Co., Ltd., a manufacturer of beverage filling equipment and packaging firm with a talented technical team and well-equipped testing facilities. We offer liquid filling systems for water, tea, carbonated drinks, alcohol, oil and plant protein drinks.), barreled filling line (: 1-5 gallon) water treatment machines, bottling capping machine, semi-automatic /full automatic PET bottle blowing machines, and injection molding machines, extrusion blow molding machines (PP/PE/PVC/PETG/PC) and accessories for automation: leak tester machines, bottle bag packing machines, conveyor belts.

We manufacture machine components using CNC machines. We are certified by CE TUV, CE, ISO9001 certification. From the layout of the plant to the manufacturing of equipment and production line set-up, we can provide the best possible service to our clients. Our products are widely known and widely used and are able to be used to meet ever-changing economic and social requirements. Now our products are exported to more than 20 countries and regions that include South America, bottling capping machine, Southeast Asia, Russia and the Commonwealth of the Independent States, Western Asia and South Africa.

With a wide range and good quality, as well as reasonable pricing and bottling capping machine Our products are widely utilized in beverage and other packaging equipment. We can assist you in designing labels for bottles, factory drawings labels, and bottles. We will keep you aware of the production schedule during the process of production. We can customize the machine to meet your requirements for power, material and type of filling bottle sizes, etc. You can visit the manufacturing facilities of our projects as reference in a variety of countries, provided you are granted permission by the customers.

We will deliver your machine on the agreed date. We will provide 2 years of free spare parts, and lifetime support following the time the product is delivered. We will offer free spare parts within 24 hours via international express professional and all-year technical support with 24/7 response from our engineers. (All services are delivered to the customer in five days using Intl courier). We are open to new and returning customers from all types of industries to reach us for bottling capping machine in the future and our mutual success!