Wine bottling is a significant work for those companies who produce the wine and sell them. The way we bottle wine is key for a variety of reasons, some which include how well the wines taste and travel to customers. Having the proper tools can make it easier and quicker for employees to accomplish this task. Wine Bottling Equipment for SaleHere are some important considerations to think about when selecting wine bottling equipment for your business!

Here are some of key factors to consider as you select wine bottling equipment. To start, consider the size of your business. Are you interested in a small machine for a boutique winery, or do you need something that processes wine all day long like the man-sized one Otto had been after this time? Next, consider your budget. What is your budget for equipment Make sure that you get something for which it suits your pocket Consider the hardware you require in a machine lastly. For example, need a machine that can fill different bottle shapes or one that takes many at once? If you think over all these things carefully then this will help in selecting the best equipment that is required by your business.

You must purchase the best quality wine bottling equipment to advance your business in many ways has Well for one it can save you time and money. The faster you can bottle wine and get it out of your winery, the better as wine costs money to make but also requires enough grapes harvested from vines AND more importantly are meters purchased with in-game coins Game economy will kill those who do not act proper. This can be very important for scale your business. 1. High-quality equipment makes better wine Proper bottling should be performed to preserve the excellent taste and aroma of wine, so good equipment is required. Your clients will hence appreciate your wine, even more! Last but definitely not least are the appropriate tools you can use to grow your business. Better equipment means more wine you can produce and put out to customers, which is good for business.

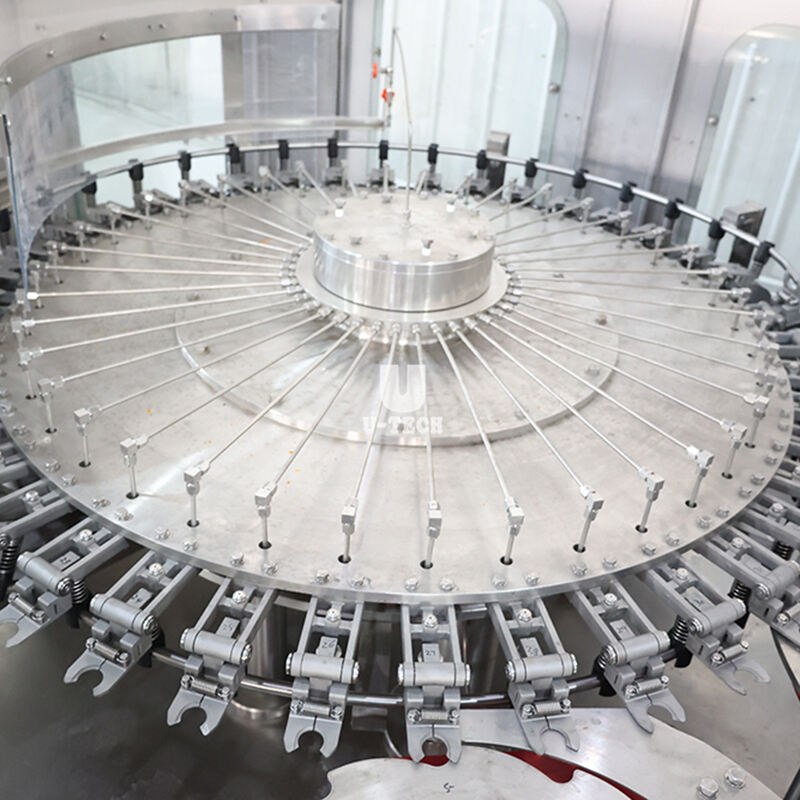

Key features to look for when choosing wine bottling equipment Pick a machine that is easy to use and maintain your machinery, first. This will save you time and money down the line, not to mention make your life easier. Second, get a machine that can handle multiple kind of bottles and caps. This will make your a lot more adaptable cause you can create wines of all different types. 3. Seek out a machine that can fill multiple bottles at once This will reduce the time it takes to work and enable you to keep up with your demand 4.) Fourth, pick a machine that can serve still wine and sparkling wine. Last but not the least, ensure that the machine is actually durable and has a warranty if it breaks. This way you know that you are putting your money in the right place.

These are other important pieces of equipment you need for effective operation independently of the right wine bottling equipments. A good corker to give you a proper seal on your bottles is recommended. This is very important to stop your wine from going bad. Next, a great wine filter is crucial to make sure your new batch of home made wine does not have any impurities in it so you won`t get sick. Third, have a great wine pump that allows seamless transfer of content from one container to another. Wine Barrel Treatement: the fourth step is to go for a good wine barrel from where you can purchase, maintaining your best redgeterat of great quality. Finally, ensure you have an efficient bottling line in place for filling and labeling your bottles promptly. Here are the tools that you should have to streamline the bottling process for yourself and your team.

With high quality wine bottling equipment the process is fast and simple so you have bottled wines to sell in no time... The wine is first filtered in case there are any impurities that may cause it to spoil its taste. After that, the wine is pumped to bottling line and bottled either with a cork or screw cap. Its pretty much from there fill bottles with content - label and check quality a make sure everything we do is perfect. Then the bottles are lovingly wrapped and put to one side until we send them out. This process can be made whole lot easy and fuel efficient to enable you have quality done with excellent wine if the proper tools are in place.

The machine will be delivered at a time as per the deadline agreed between both parties. Following delivery of the product, we'll offer 2 years of no-cost spare parts and lifetime support. We will offer free spare parts in 24 hours via wine bottling equipment and lifetime technical support with 24 hour engineer response. (All services will be delivered to the customer within 5 days via Intl courier). Contact us today to establish mutually beneficial business relationships with current and new customers.

We manufacture machine components using CNC machines. We are certified by CE TUV, CE, ISO9001 certification. From the layout of the plant to the manufacturing of equipment and production line set-up, we can provide the best possible service to our clients. Our products are widely known and widely used and are able to be used to meet ever-changing economic and social requirements. Now our products are exported to more than 20 countries and regions that include South America, wine bottling equipment, Southeast Asia, Russia and the Commonwealth of the Independent States, Western Asia and South Africa.

With a wide range, good quality, reasonable costs and attractive designs Our products are widely utilized in wine bottling equipment and other packing equipment. We design bottles, labels as well as factory drawings. We will keep you updated of the timetable for production during the process of production. We will customise the machine to your specific requirements such as material, power and type of filling bottle styles, etc. You can visit the factories of our projects as reference across the globe if you are granted permission by the customers.

Zhangjiagang U Tech Machine Co., Ltd., a manufacturer of beverage filling machines and packaging company with a seasoned wine bottling equipment as well as well-equipped test facilities. Our products include: liquid filling equipment (water and fruit juice/tea, carbonated drink, oil alcohol, plant protein drink, etc.), barreled filling line (: 1-5 gallon) water treatment machines, labeling packing machines, semi-automatic /full automatic PET bottle blowing machines, and injection molding machines, extrusion blow molding machines (PP/PE/PVC/PETG/PC) and accessories for automation: leak tester machines, bottle bag packing machines, conveyor belts.