Do you handle a company that uses tiny bottles, each including some type of fluid cleansing your skin. They may hold anything from strong chemicals to beauty products, and consumables such as alcohol or juice. The inclusion of this machine within your activities results in general making the manufacturing process simpler as well and makes it possible to produce goods on a higher-quality. Producing Higher with High-Speed Small Bottle Filling Machine

Adding a high-speed small bottle filling machine to your workflow is more beneficial for you in the long run. Having a wide throughput capability of 120 bottles per minute, the machine guarantees that orders are processed with high precision and speed providing lesser margin for error. What is more, it can handle both the free-range of various shapes and sizes starting from 2ml to 500 ml.

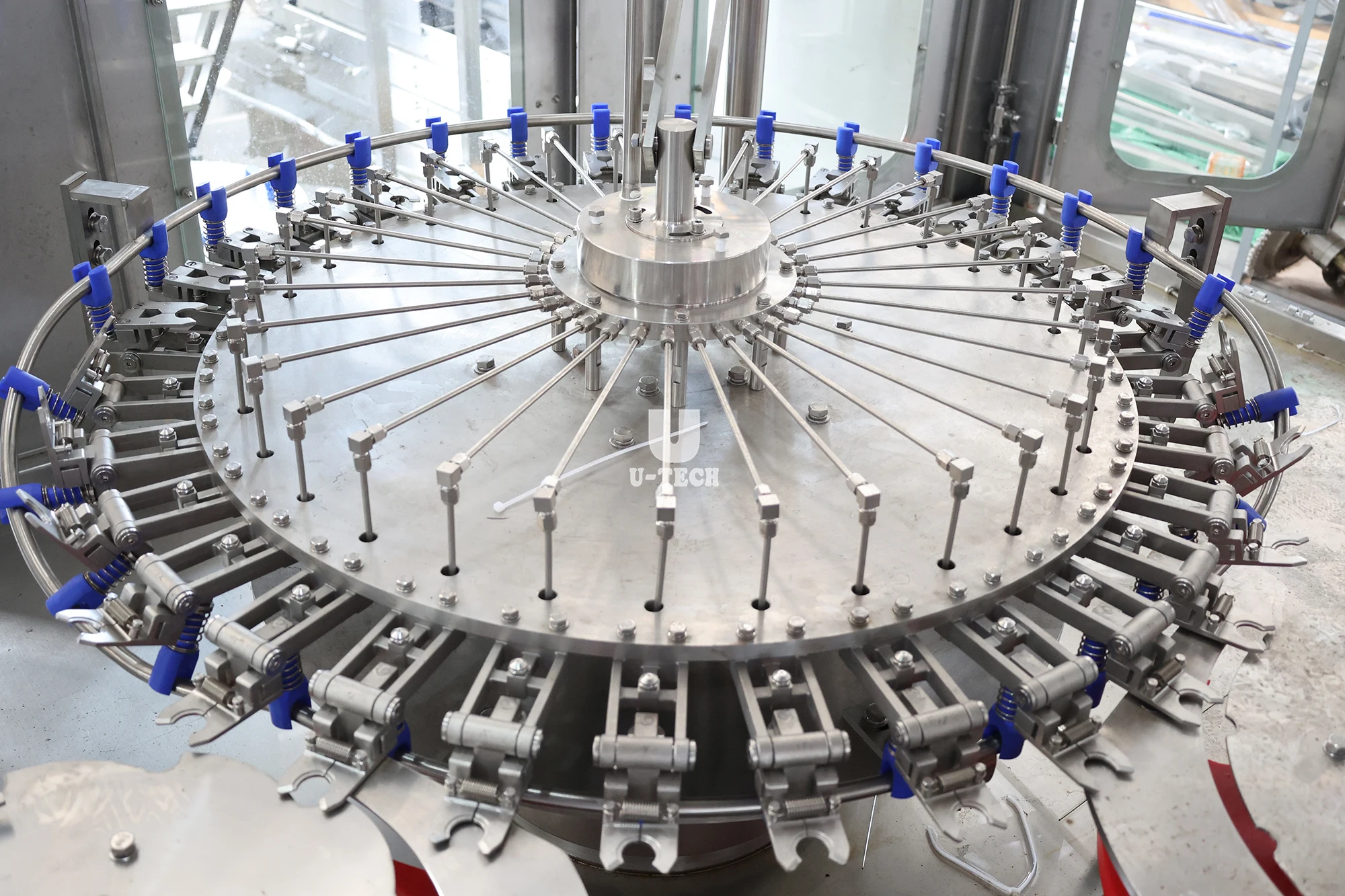

Small bottle filling machine is used in various industries such that the utility of this small product processor can be found across a wide area. Alongside U Tech filling and capping machine it is possible for the machine to fill beverages like this, as well as air fresheners, chemicals and pesticides among others. Last but not least, this machine offers significant value because of its versatility in a range of manufacturing processes.

In a project such as alkaline water plant, the use of small bottle filling machine that is high-quality will ensure both unmatchable accuracy and precision in the fill process. The U Tech oil bottle filling machine high precision, with +/ 0.5 % fill volume accuracy allows this production of fine goods to meet customer requirements time and again in terms of quality

Besides, incorporating self-cleaning features is a great way to make your workplace safer and cleaner which minimizes the chances of getting contaminated. Having a small U Tech filling machine is an investment that not only streamlines your production but also helps maintain quality in delivering products to customers.

We Small bottle filling machine machine parts using a CNC machine. We are certified by CE, TUV and ISO9001. From layout of plants to equipment manufacturing and production line installation, we provide the highest level of service to our customers. Our products are widely known as well as widely trusted, and they can adapt to ever-changing economic and social requirements. Nowadays, our products are being exported to over twenty countries and regions which include South America, Middle East, Southeast Asia, Russia as well as the Commonwealth of the Independent States, Western Asia and South Africa.

We will deliver your machine on the agreed date. We will provide 2 years of free spare parts, and lifetime support following the time the product is delivered. We will offer free spare parts within 24 hours via international express professional and all-year technical support with 24/7 response from our engineers. (All services are delivered to the customer in five days using Intl courier). We are open to new and returning customers from all types of industries to reach us for Small bottle filling machine in the future and our mutual success!

Small bottle filling machine a beverage filling machine manufacturer and packaging business with a talented technical team and well-equipped test facilities. We provide liquid filling equipment for tea, water, carbonated beverages, alcohol, and protein-rich drinks made from plant.), barreled filling line (: 1-5 gallon) water treatment machines, labeling packing machines, semi-automatic /full automatic PET bottle blowing machines, and injection molding machines, extrusion blow molding machines (PP/PE/PVC/PETG/PC) and accessories for automation: leak tester machines, bottle bag packing machines, conveyor belts.

Our products are extensively used to make beverage and other packaging equipment due to their extensive selection, quality, low cost and Small bottle filling machine. We design bottles, labels as well as factory drawings. We will keep you updated of the production schedule during the production process. We will customise the machine to your specific requirements for power, material as well as the type of filling bottle sizes, etc. Visit the factories of our reference projects across the globe if you get permission from the customers.