Have you ever taken the time to consider how oil bottles are filled before they reach shoppers at home? Well, that really IS interesting! No, because the oil bottle filling machine a school of thought and an invention unto its own which makes this process effortless as well & quick.

No longer will hours of time (and gallons of energy) be spent on filling bottles one by one. The oil bottle filling machine takes all that burden off you, whenever the time ticks to refill one of those bottles it's as simple pouring an oil into the machine and watch a wonder work swiftly in front your eyes right before every single drop is accurately filled up each bottle with absolute precision.

If you are among those producing oil bottles on a massive scale, then it is very important to fill them as fast and efficiently as possible. This is where an automated oil bottle filling machine enters the picture!

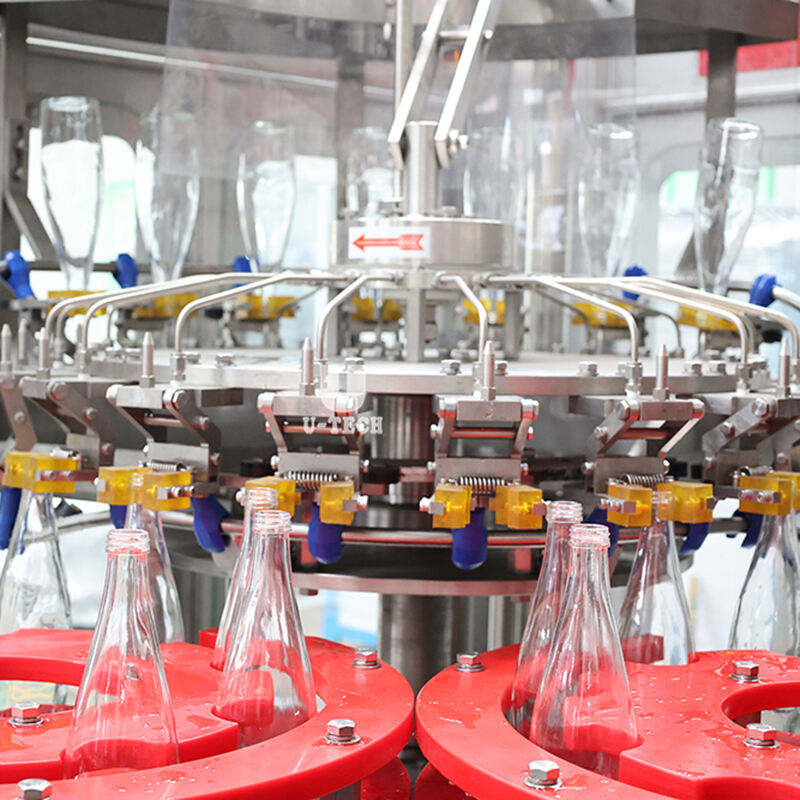

This engineering marvel makes the production process miles easier and smoother. This does not happen when we are filling it manually like the above process is performing but what if this work can be done with a machine where our time as well as labor both saved and also fill multiple bottles at the same time? Furthermore, its compatibility to any size bottle variety makes useful in a nearby managed area oil manufacturing enterprise.

Filling Perfume Bottles Accurately by Hand One of the biggest challenges to manually filling oil bottles is that you can have spills or over-fills wasting both time and resources. But, by using an oil bottle filling machine you can get rid of all these worries.

This machine is incorporated with high-end technologies that instigate and make sure every bottle gets filled up with right amount of oil. It even includes a smart system that will know when the bottle is full, and stop itself from being overfilled. This allows you to provide your customers with extremely reliable products on a regular basis.

The business world is all about satisfying customer needs on time. A high-speed machine can be that invaluable addition to the line if you are faced with overcoming shorthandedness in production.

Zhangjiagang U Tech Machine Co., Ltd. is a supplier of beverage filling machines and packaging with well-equipped testing facilities and oil bottle filling machine. We provide liquid filling equipment for tea, water, carbonated drinks, alcohol, oil and protein-rich drinks made from plant.), barreled filling line (: 1-5 gallon) water treatment machines, labeling packing machines, semi-automatic /full automatic PET bottle blowing machines, and injection molding machines, extrusion blow molding machines (PP/PE/PVC/PETG/PC) and accessories for automation: leak tester machines, bottle bag packing machines, conveyor belts.

We create machine parts with a CNC machine. We hold CE TUV, CE, oil bottle filling machine certification. From plant layout to production equipment manufacture and line set-up, we can provide the highest level of service to our clients. Our products are well-known and trusted by users and can meet continuously changing social and economic needs. Our products are now exported to more than 20 countries and regions that include South America, Middle East, Southeast Asia, Russia, the Commonwealth of the Independent States, Western Asia and South Africa.

The oil bottle filling machine will be delivered on time to the time frame agreed upon by both parties. We will give 2 years spare parts free of charge, and lifetime support after the product is delivered. We will supply free spare parts 24 hours a day through international professional express as well as lifetime technical support with 24-hour response from engineers. (All services will be delivered to the customer within 5 days by Intl courier). Contact us to establish positive business relations with new and existing customers.

With a variety of products with good quality, oil bottle filling machine, and fashionable designs our products are extensively used in beverage as well as other packing equipment. We design bottles, labels, factory drawings, etc. We will keep you aware of the production schedule during the production process. We will design the machine according to your requirements, materials power, filling types, the kinds of the bottles and so on. You can visit the factories of our project references in many countries if you are granted permission by the customers.