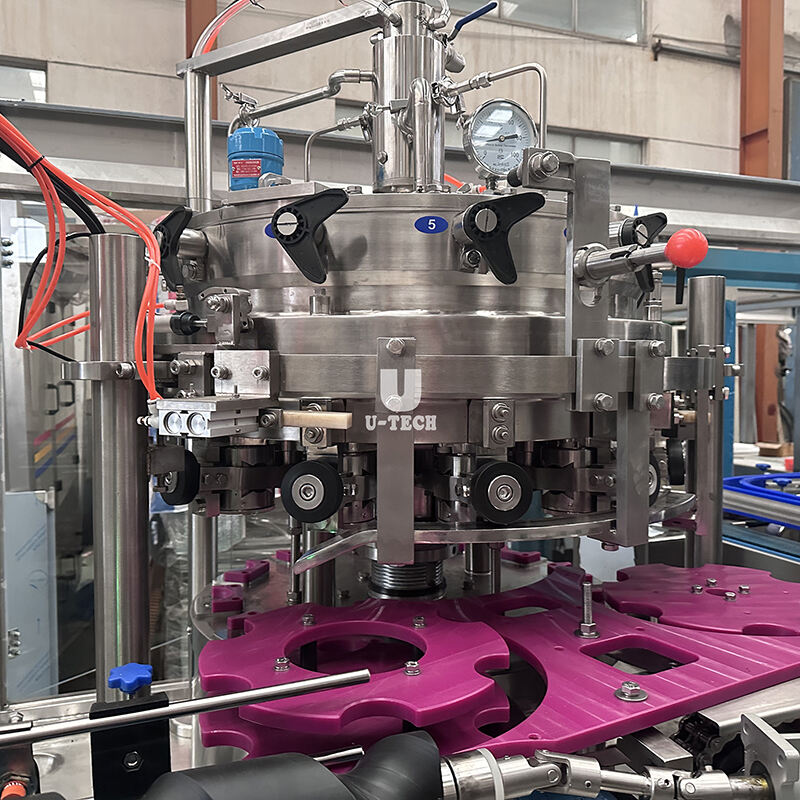

Ever wonder how your favorite beverages or snacks are packed so efficiently? It's really interesting. Even the mono block filling and capping machines do this special work which you might not know. This U Tech filling and capping machine is in working operation producing containers filled with food stuffs, or beverages that have tight seals on them. This sealing is highly significant so as these products can be delivered to the stores without any issue.

Have you ever heard of what airtight means? It’s a neat word. Airtight — No Air Can Get In or Out of the Container Such measures are hugely important in preserving the longevity of our food. Why is that? Oxygen could be the spoilage of food or make it rotten quickly if got into by air. No one wants to eat foolish food, eh? A mono block filling and capping machine ensures tightly-sealed containers. This helps things like our food last longer so those who love tasty snacks and beverages always have some on hand.

You know that word efficiency? The word is long but the meaning here simple! Efficiency is doing things right and making sure nothing goes to waste. The monoblock filling and capping machine is highly productive as it can fill numerous containers very quickly. This Is Great for Factories, Because The U Tech filling and capping machine can Produce More Product in Less Time It means we receive more of our favorite snacks and drinks much faster when factories are running quickly and efficiently. At the end of it all, these machines help us have more yummy goodness lying in our fridges and freezers.

Ever think about the price of packaging food? That can actually be quite a lot. The good news however; the monoblock filling and capping machine saves a lot of money because it functions like many machines in one. This additionally ensures that factories do not have to spend more money on purchasing several machines or employing many workers for a single work. This in turn helps keep the prices on our favored products affordable as these same factories slash costs with their packaging. That means we can purchase more of our coveted items at a budget-friendly price.

Results of Monoblock Filling and Capping Machine is used more in factories. It can seal all types of food in advance and it is very fast saving you money. With these many advantages, it is clear why these machines are so sought after. And they are also important to the fact that we can eat our beloved products fresh and delicious. Now, each and every time that you sip your drink or eat from the can/ bottle, just be reminded that there are such fantastic machines as the U Tech monoblock bottle filling machine which goes all throughout to help keep all of these things robustly packed.

Zhangjiagang U Tech Machine Co., Ltd., a beverage filling machine maker and packaging firm with a talented technical team and well-equipped test facilities. We supply liquid filling machines for tea, water, carbonated beverages, alcohol, oil and plant protein drinks.), Monoblock filling and capping machine (: 1-5 gallon) water treatment machines, labeling packing machines, semi-automatic /full automatic PET bottle blowing machines, and injection molding machines, extrusion blow molding machines (PP/PE/PVC/PETG/PC) and accessories for automation: leak tester machines, bottle bag packing machines, conveyor belts.

The Monoblock filling and capping machine will be delivered on time to the time frame agreed upon by both parties. We will give 2 years spare parts free of charge, and lifetime support after the product is delivered. We will supply free spare parts 24 hours a day through international professional express as well as lifetime technical support with 24-hour response from engineers. (All services will be delivered to the customer within 5 days by Intl courier). Contact us to establish positive business relations with new and existing customers.

With a wide range, good quality, reasonable pricing and trendy designs, our products are Monoblock filling and capping machine in beverage and other packaging equipment. We can help you design the factory drawing, bottles labels, bottles and so on. In the course of machine production we will adjust the your production schedule on time. We can modify the machine to meet your requirements in terms of material, power as well as the type of filling bottle sizes, etc. We have reference projects in a variety of countries and can take you to their factories once we have the approval of the customer.

We make machine parts with CNC machines. We are certified by Monoblock filling and capping machine, TUV and ISO9001. From layout of plants to the manufacturing of equipment and production line setup, we are able to offer the best service for our customers. Our products are well-known as well as widely trusted, and they can meet constantly changing needs in social and economic conditions. Our products are sold to more than 20 countries, including South America and the Middle East. They also go to Southeast Asia, Russia and the Commonwealth of Independent State.