Have you ever imagined how the mustard oil is bottled before they are sold at stores? A machine called a mustard oil bottle filling machine do this task. Mechy fills the bottles with the exact quantity of mustard oil These are very time-consuming and gives a flexibility to the workers in factory. This machine saves a great deal of time and energy for the workers; removing it from service would cause them to fall way behind.

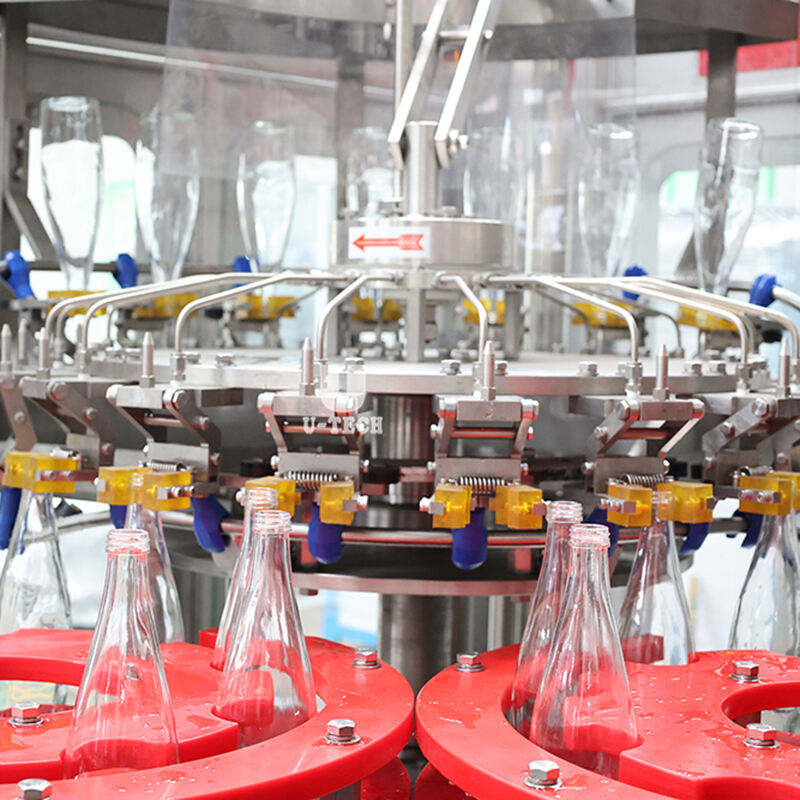

There are components that function together in a machine A conveyor then transported the empty bottles from one location to another. There is a nozzle that fills those bottles with oil next. Then there is another filling machine for putting the caps on top of bottles when they are filled. This system is standalone, meaning everything does not need to be done by hand. This automation leads to smooth and efficient functioning of the factory.

It was filled by hand in Mustard oil bottles a way back. This would entail blatantly measuring each bottle before pouring oil into the cavity. It was laborious work and took many hours, as they had to watch the line of bottles closely to ensure that each got fill with just enough oil. This was no less a religious duty then ploughing, and it required many men to perform these rites.

With the new mustard oil filling machines, it is now simple and quick for factories to fill those bottles. The machine fills many bottles simultaneously. This is not only a time-save but it also means that the work requires fewer people. This saves some money when controlling the machines so that manufacturers get their work done efficiently.

Unfortunately, errors can occur when filling bottles by hand. Some bottles get more oil and some less, an example of this. The subsequent problem that it causes is by virtue of the quality not, again a positive thing for you. Nobody wants low quality or inconsistent mustard oil. And with a mustard oil filling machine, All bottles get filled with same quantity of Oil only. This is why the customers always enjoy a perfect product whenever they purchase mustard oil. Thanks to this machine, each bottle is balanced properly.

This kind of mustard oil filling machine not only saves the labor and cost for a factory but also help them make more money. And since the machine does not sleep, take a break or weeks of leave, more bottles can be produced in less time. The result is they can respond to customer requests more smoothly.

It also uses fewer workers, cutting labor costs. This filling machine does the job of making sure that the right amount get into all bottles which ensures continuous high-grade product quality for customers. This in turn can lead to more sales and increased profit making for the factory. If customers are pleased with the product or service, Naturally this can lead to repeat business which is always good for your bottom line.

With a variety of products with good quality, competitive pricing and trendy designs our products are extensively employed in beverage and other packaging equipment. We can design bottles, labels, factory drawings, etc. When the machine is in production we will make changes to the production schedule for you on the appropriate date. We will customise the machine to meet your specifications such as material, power and filling type, bottles, and so on. We have reference projects in a variety of countries and we can show you their facilities if we have the mustard oil bottle filling machine.

The mustard oil bottle filling machine will be delivered on time to the time frame agreed upon by both parties. We will give 2 years spare parts free of charge, and lifetime support after the product is delivered. We will supply free spare parts 24 hours a day through international professional express as well as lifetime technical support with 24-hour response from engineers. (All services will be delivered to the customer within 5 days by Intl courier). Contact us to establish positive business relations with new and existing customers.

mustard oil bottle filling machine a beverage filling machine manufacturer and packaging business with a talented technical team and well-equipped test facilities. We provide liquid filling equipment for tea, water, carbonated beverages, alcohol, and protein-rich drinks made from plant.), barreled filling line (: 1-5 gallon) water treatment machines, labeling packing machines, semi-automatic /full automatic PET bottle blowing machines, and injection molding machines, extrusion blow molding machines (PP/PE/PVC/PETG/PC) and accessories for automation: leak tester machines, bottle bag packing machines, conveyor belts.

We create machine parts with a CNC machine. We hold CE TUV, CE, mustard oil bottle filling machine certification. From plant layout to production equipment manufacture and line set-up, we can provide the highest level of service to our clients. Our products are well-known and trusted by users and can meet continuously changing social and economic needs. Our products are now exported to more than 20 countries and regions that include South America, Middle East, Southeast Asia, Russia, the Commonwealth of the Independent States, Western Asia and South Africa.