One such machine is the monoblock bottle filling machine, Different types of bottles designed to be filled with liquids using this machine. Some of these liquids are water, soft drinks, juice and hair shampoo. To fill the bottles very easily and accurately, The monoblock bottle filling machine is drastically significant. Which allows companies to produce a great amount of items at the same time and in this way not make mistakes.

The monoblock bottle filling machine is used very quickly, and this was one of the main reasons people choose to use it. It can fill thousands of bottles in just one hour, infact! So the speed is a relative important matter for companies because they wants to make their products fast. The faster they can fill bottles the more items to be sold thus earn some money. If a machine can make the process of bottling up faster, it means that bottles are filled up at an incredible rate and makes the company operate even more grandly. This, in turn means workers are able to concentrate on more significant work as they know the machine would be doing it.

The monoblock bottle filling machine is also automated which makes its more attractive. So, a computer is anything that works as directed by the program. This means that we are able to ensure the same liquid level in every bottle — a huge advantage. Because if the bottles are being filled by hand there is a possibility that they wont all be equal. It may present some problems for the company. But the machine is super consistent — every bottle gets filled exactly same way so they really are a higher-quality product.

The monoblock bottle filling machine has a very slim configuration as well. This makes it very ideal for a place in the factory or even a production area. Companies need to be very economical with their space, and this is quite reasonable. They do not have space for a large machine as they need to make room for other types of equipment and employees. So this allows room for organizations to actually organize and work save cost much easier by using a small machine that does it in volume.

And also, it can fill different types of liquids and bottles as well so that is a great thing to have right there. That is very helpful because a company makes different products which need to be bottled differently. So if you have a company making shampoo, is different from your juice plantation company. for the former probably has to fill bottles in various sizes than those generally needed by the latter. This is because companies are able to use one machine for multiple types of bottles and liquids meaning they do not have to purchase a different machine everytime the make something new.

The monoblock bottle filling machine is helpful in assisting companies to work more efficiently. They save time and money by fast and precise filling in bottles, Companies can therefore deliver more products in a faster time frame. They can sell more and make finally profit, when they can produce a greater number of items in less time. This is crucial because businesses have to make money in order for the lights to stay on, their employees working.

We will deliver the machine on time to the date set by both parties. Following the delivery of the item, we will give monoblock bottle filling machine of complimentary spare parts and lifetime support. We will provide free spare parts in time within 24 hours through international professional express, and offer lifetime technical support for the machine, 24/7 for response from engineers (all services part 5days in the customer's hands by Intl' Courier). We welcome new and old customers from all types of industries to reach us for future business partnerships and the mutual benefit!

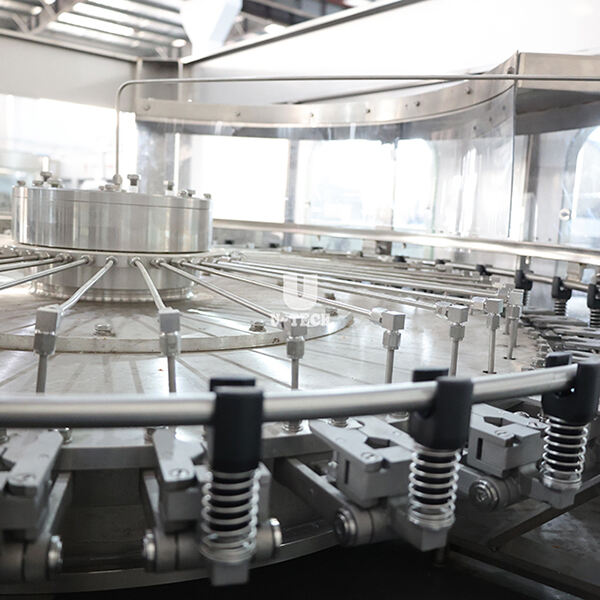

We make machine parts with CNC machines. We are accredited by CE, monoblock bottle filling machine and ISO9001. We provide the highest quality of services for our customers, starting including plant layout production equipment, layout and line configuration to operator training as well as the most efficient after-sales service. Our products are widely recognized and trusted by consumers and can meet continuously changing requirements in social and economic conditions. Our products are currently exported to more than 20 countries including South America and the Middle East. They also export to Southeast Asia, Russia and the Commonwealth of Independent States.

Zhangjiagang U Tech Machine Co., Ltd., a manufacturer of beverage filling machines and packaging company with a seasoned monoblock bottle filling machine as well as well-equipped test facilities. Our products include: liquid filling equipment (water and fruit juice/tea, carbonated drink, oil alcohol, plant protein drink, etc.), barreled filling line (: 1-5 gallon) water treatment machines, labeling packing machines, semi-automatic /full automatic PET bottle blowing machines, and injection molding machines, extrusion blow molding machines (PP/PE/PVC/PETG/PC) and accessories for automation: leak tester machines, bottle bag packing machines, conveyor belts.

Our products are extensively used for packaging beverages and other equipment due to their broad selection, quality, affordable prices and attractive designs. We can design bottles, labels or monoblock bottle filling machine. We will keep you informed of the schedule for production throughout the process of production. We will customize the machine in accordance with your requirements, materials power, filling type and the types of bottles and the like. You can visit the manufacturing facilities of our project references across the world if you have permission from customers.