A drink like well, milk of whatever kind would have universal appeal because everyone everywhere drinks water right? This U Tech milk bottle filling machine important nutrient forms strong bones and teeth. We might like corn but we are just lost without our milk. Milk is sent through a bottling procedure to give us milk. Similar other harder labours are also putting in their efforts to make this process easy and quick for us so that we can have the taste of fresh milk daily.

Re: Bottling plant packing of fresh milk for groupies consuming all the saucer? ! It is an essential commodity for humans, thus it must be the fresh, lively milk from those cows as they thrive on farms; save the milk or else. First Step First and foremost, the milk is heated at a very high temperature to eliminate any bacteria or viruses that could make us sick. This process is known as pasteurization. After that, the milk is packaged in half-pint, pint, quart, and gallon sizes. It is also labelled so that we can identify what type of milk is in each bottle and will be able to provide information about the contents – for example, a level of nutrition for baby employer organisation.

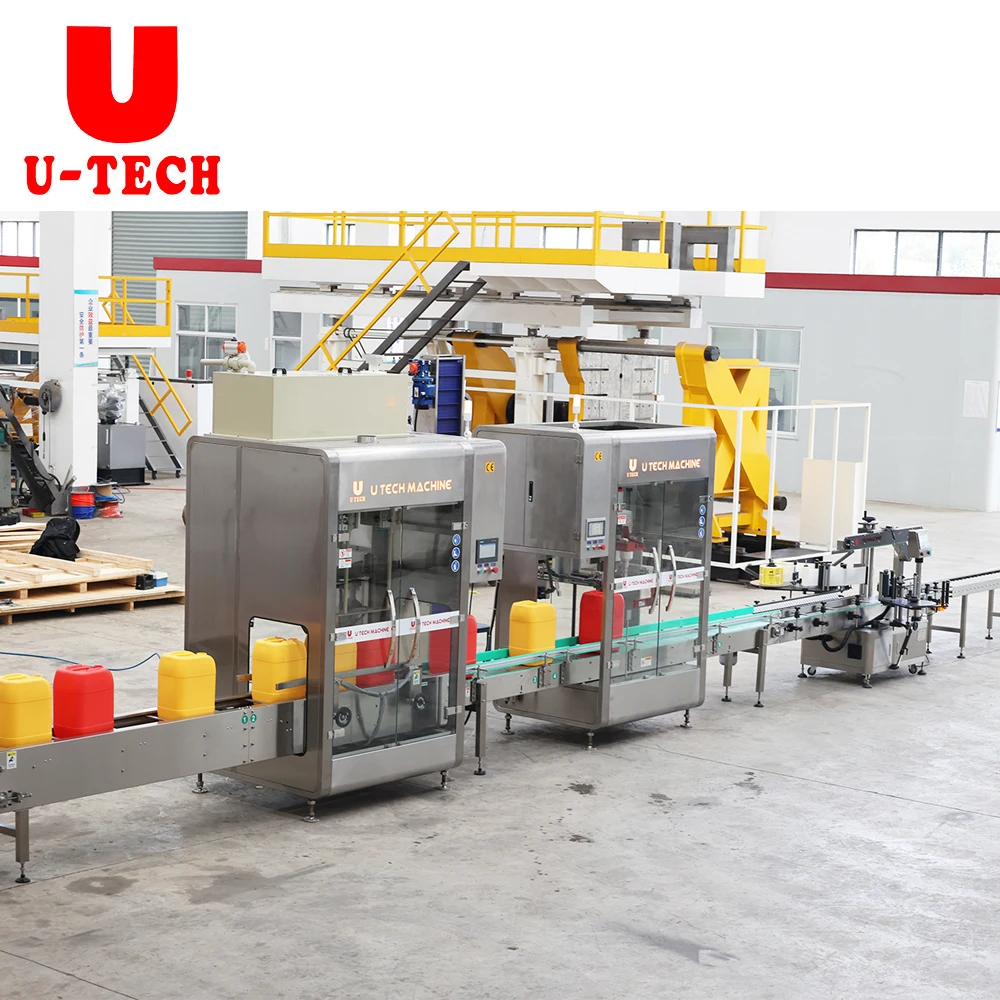

Today, however, technology allows things to be bottled in a much quicker and cleaner way. Special machines are much more efficient than a group of people filling, capping and labeling gallons upon gallons after all. These milk bottling equipment U Tech can be used continuously, 24 hours a day as these do not take any break and hence produce many milk bottles in just no time. They also work to maintain a clean, safe environment a place where milk will be healthy for us. They do this by consuming all pests preventing us or our cows from being bitten and driving pollinating insects out of business.

In the process of milk bottling, there are specific essential steps that need to be followed. Type of inspection for verifying safety. Seasonal Factors. Milk is moved from the farm to the processing plant. The milk goes through an initial batch test. This examination is crucial since we need to guarantee that the milk remains safe for us. After that, the milk is pasteurized at 161° F (72 °C) for only a few seconds to eliminate all bacteria that could spoil it and is then quickly cooled to temperatures just above freezing. It is sent to the bottling line in various bottle sizes: Choose which one you prefer. The label on each bottle also indicates the amount of fat and protein, in addition to the vitamins it contains. The new bottles are subsequently packed into cartons which are then transported to the stores for our consumption.

The people wanted their fresh milk to last long, and the machines helped to package it so we can take just that back home. This U Tech milk bottling machine makes the bottles get filled so quickly and sealed to prove it is safe for drinking or not. To that end, it should be no surprise there are light technology solutions for keeping your milk fresh longer and eliminating bad germs. That way, we get the opportunity to drink our india milk before it disappears.

With a wide range and good quality, as well as reasonable pricing and Milk bottling lines Our products are widely utilized in beverage and other packaging equipment. We can assist you in designing labels for bottles, factory drawings labels, and bottles. We will keep you aware of the production schedule during the process of production. We can customize the machine to meet your requirements for power, material and type of filling bottle sizes, etc. You can visit the manufacturing facilities of our projects as reference in a variety of countries, provided you are granted permission by the customers.

Milk bottling lines a beverage filling machine manufacturer and packaging business with a talented technical team and well-equipped test facilities. We provide liquid filling equipment for tea, water, carbonated beverages, alcohol, and protein-rich drinks made from plant.), barreled filling line (: 1-5 gallon) water treatment machines, labeling packing machines, semi-automatic /full automatic PET bottle blowing machines, and injection molding machines, extrusion blow molding machines (PP/PE/PVC/PETG/PC) and accessories for automation: leak tester machines, bottle bag packing machines, conveyor belts.

We make Milk bottling lines by CNC machine. We are certified by CE TUV, CE, ISO9001 certification. We offer the best service to our customers, ranging from layout of the plant manufacturing equipment and production line setup to operator training and best after-sales service. Our products are admired and trusted by users and are able to meet ever-changing economic and social needs. Our products are currently exported to more than twenty countries including South America and the Middle East. They also export to Southeast Asia, Russia and the Commonwealth of Independent States.

We will deliver the machine on time according to the date agreed by both parties. Once we have delivered the product, we'll provide 2 years of free spare parts as well as lifetime support. We will ship spare parts within Milk bottling lines using international professional express. We also offer lifetime technical support for your machine, 24 hours for engineer response (all support services will be provided for 5 days after delivery to the hands of the customer by Intl' courier). Contact us to establish positive business relations with current and new customers.