Once you have made hot sauce, bottling it can be challenging. When you fill the bottles, it is important to hit that right amount. Fill them too much and they overflow, fill them not enough, and the taste is just off. It can alter the taste of the hot sauce people love if you get this wrong. On the pros side, there are a fair number of machines designed just for bottling hot sauce that truly rule. Such machines are framed to fill the bottles accurately, promptly. They come in various sizes, therefore you can take the best fit for your business. This allows you to determine the machine that accommodates your production space and how much hot sauce you want bottled.

In the hot sauce business, time is of great importance. Cybercriminals tend to be in a hurry, getting your product there faster than others is another reason you need an AWA specialist. This is where bottling equipment comes in handy. You can go for a machine in order to fill up the bottles without spending oodles of time filling them one by one with your own hands. This saves you a lot of time and ensures your operations are still running correctly. The machines prevent leaks, so no hot sauce is wasted. Not only is throwing product away just giving money out the door, but loosing your assent! Just spout off a little more hot sauce...more quickly and for less money spent on labor once you get going with the right equipment. Ingres Note: With Our Sauce & Hot Newsletters you can stay clear of doing this and instead concentrate on making the HOTTEST sauce around and constructing your service!

One of the main operations (and time-consuming) is to fill hot sauce bottles and, based on skills, we may be able to supply a lot or just few. An automatic bottling system is a fantastic start. Such machines fill the bottles rapidly and precisely - resulting in complete wherewithal for plentiful hot sauce production-time. A: The use of machines allows you to maintain the quality and this guarantees that your customers are satisfied with what is served in their tables. Automated systems will also save you the cost of workers, saving your business money in other areas. This is where investing in this technology equips you with an efficient production capability that caters to your customer needs.

Packaging Hot Sauce, Safety First Therefore, it is important that everything be done safely so as to protect your product and the workers working on the Motors. Which is why you must use machines specifically designed to safely and accurately screw caps onto hot sauce bottles. The machines are compatible with your selected bottle types of sizes also so they can adjust according to the bottles size. They help fill the hot sauce and ensure that it goes in correct, which means spills happen less often so you lose much fewer products. Hot sauce is a mighty addition to most of meat dishes, however it´s good not to foregit about safety. From a low-resistance lead to the proper clip connection, these simple purchases create a safer work environment for all.

Well, every business is unique and that's why they need a machine to cater for what makes hot sauce processing different. You run these machines on various sizes of bottles or packages, to adjust according the need and size for you production output. Depending on your kind of production line you look for: you may find machines with additional features like labelling, capping and sealing. But the even worse news is that this basically means you force your business to fit onto a process someone else wants, with little configurability. In practice, this means that you can bottle your hot sauce in less time and spend more on what makes you so unique.

The machine will be delivered at a time as per the deadline agreed between both parties. Following delivery of the product, we'll offer 2 years of no-cost spare parts and lifetime support. We will offer free spare parts in 24 hours via hot sauce bottling equipment and lifetime technical support with 24 hour engineer response. (All services will be delivered to the customer within 5 days via Intl courier). Contact us today to establish mutually beneficial business relationships with current and new customers.

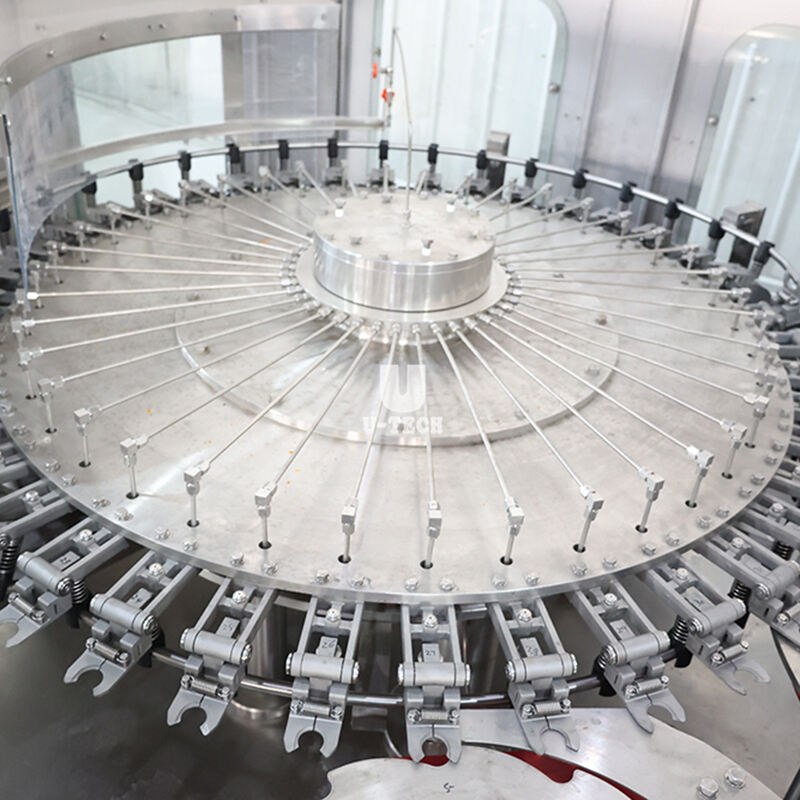

Zhangjiagang U Tech Machine Co., Ltd., a manufacturer of beverage filling equipment and packaging firm with a talented technical team and well-equipped testing facilities. We offer liquid filling systems for water, tea, carbonated drinks, alcohol, oil and plant protein drinks.), barreled filling line (: 1-5 gallon) water treatment machines, hot sauce bottling equipment, semi-automatic /full automatic PET bottle blowing machines, and injection molding machines, extrusion blow molding machines (PP/PE/PVC/PETG/PC) and accessories for automation: leak tester machines, bottle bag packing machines, conveyor belts.

We design and manufacture parts for machines using CNC machine. We are accredited by CE TUV, CE, and ISO9001. From the layout of the plant to manufacturing equipment and production line installation, we offer the best service for our customers. Our products are well-known and trusted by consumers and are able to meet ever-changing requirements in social and economic conditions. Now our products are exported across more than twenty countries and regions which include South America, Middle East, hot sauce bottling equipment, Russia, the Commonwealth of the Independent States, Western Asia and South Africa.

With a wide range, good quality, reasonable pricing and trendy designs, our products are hot sauce bottling equipment in beverage and other packaging equipment. We can help you design the factory drawing, bottles labels, bottles and so on. In the course of machine production we will adjust the your production schedule on time. We can modify the machine to meet your requirements in terms of material, power as well as the type of filling bottle sizes, etc. We have reference projects in a variety of countries and can take you to their factories once we have the approval of the customer.