In a general way, bottle filling plant is being referred for where machinery are facilitated used to accomplish the task of bottle filling with various kinds of drinks which may be water, soda or juice. As this equipment is designed to be efficient and high-speed, it can fill number of bottles in one go. As the bottles are conveyed by machines to process them, they quickly do so as well: filling each bottle with metric tons of honey in liquid volume. It is important because it saves time and makes room to bottle large number of drinks.

High technology works to facilitate the high level production that is found in any given bottle filling plant and not only can you have machines which will inspect or check for various problems on those bottles, but then again they should also enable a line with them fully satisfied of liquid. So that way, this is super crucial to do too because it keeps us only using the best of bottles. Bottles are labeledBabyGym also carries some methods of machine labeling so that the bottles identify as they must be carrying needed information. Even better yet, most of these machines work independently so you do not have to keep a person with it all the time! Such automation makes the whole process faster and also ease life for them

Trends in recent years Bottling Plants which turn to environmental alternatives They are able to reduce the level of water used during bottling for example. An energy-saving attitude Besides, some factories are running on green energies - e. g.Solar or wind power plants to run the machines. These are the little bits for us that, not only help mitigate its impact on the environment but also all compound to grow a more environmentally sustainable space.

In addition, the bottle filling plants can be customized to suit specific company needs. This allows the design of plants that are capable to change depending on whether a bottle is 1 liter or 2 liters, beer filling will take place within pilsener bottle and output in number of bottles per hour. For instance, there still is a factory for filling the carbonated drinks but also smaller factories that focus on various types of ready-to-drink bottles or larger counterparts. A shaper will become a company change machine faster than just about any piece of machining equipment it has, especially if programmed for low mix high volume production (run the job & reload) with no set up between jobs.

Bottling/ Plant to fill water bottles motoiert for future, thinking smarter and better_FILL YOUR BOTTLED WATER PLANT SMART FOR THE FUTURE For instance, certain factories will employ machines capable of filling many bottles at one time. Before, you had to fill them in one by none of the time and effort. More plants obtain machinery that can fill bottles of many different types and styles with a multitude of drinks in one operation. It is one piece that makes all over the system efficiency and item weapons development, as I also consider to their hard in order to do for it.

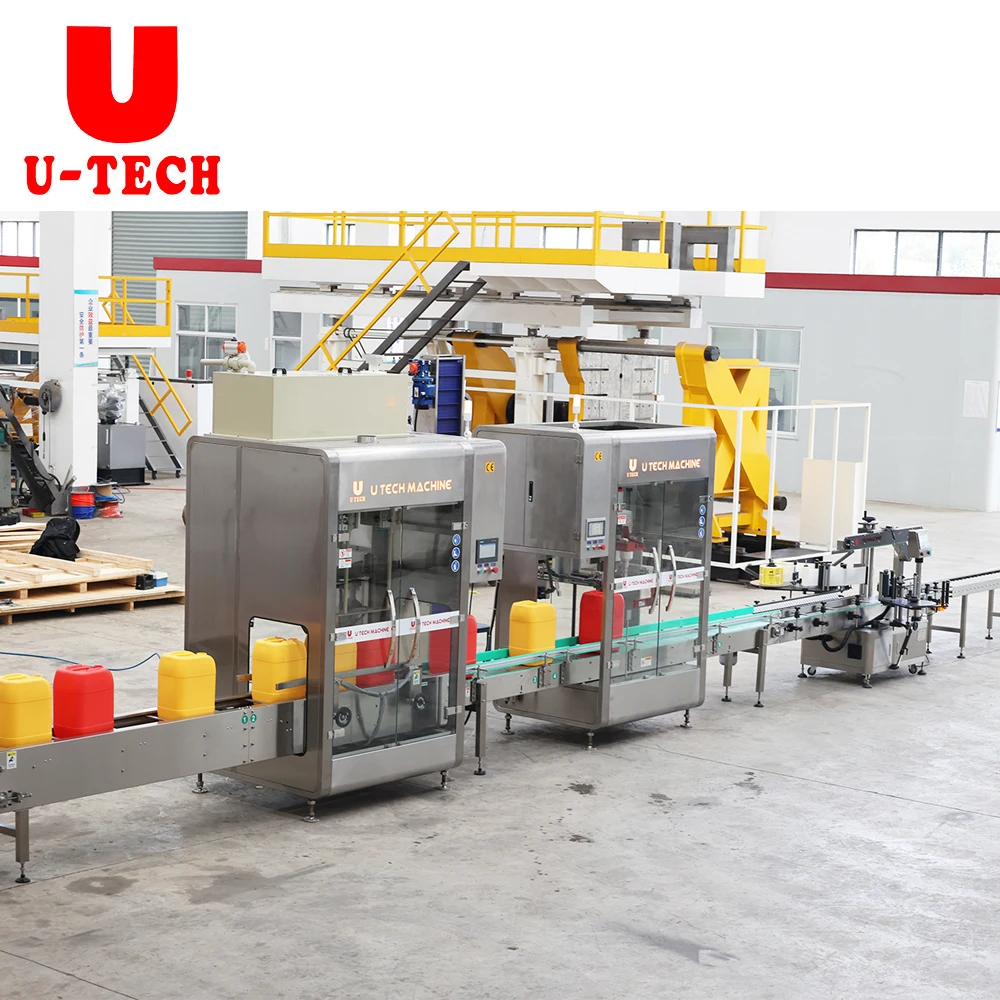

We manufacture machine parts using a CNC machine. We are accredited by CE TUV, CE, and ISO9001. We are able to provide bottle filling plant for our clients, including plant layout manufacturing equipment and production line configuration to operator training and top after-sales services. Our products are well-known and trusted by consumers and are able to meet ever-changing demands in the social and economic spheres. Our products are now exported to more than 20 countries and regions which include South America, Middle East, Southeast Asia, Russia as well as the Commonwealth of the Independent States, Western Asia and South Africa.

Zhangjiagang U Tech Machine Co., Ltd. is an exporter of beverage filling machine and packing equipment with well-equipped testing facilities and a strong force of technology. We offer bottle filling plant for tea, water, carbonated drinks, alcohol, oil and protein-rich drinks made from plant.), barreled filling line (: 1-5 gallon) water treatment machines, labeling packing machines, semi-automatic /full automatic PET bottle blowing machines, and injection molding machines, extrusion blow molding machines (PP/PE/PVC/PETG/PC) and accessories for automation: leak tester machines, bottle bag packing machines, conveyor belts.

The bottle filling plant will be delivered on time to the time frame agreed upon by both parties. We will give 2 years spare parts free of charge, and lifetime support after the product is delivered. We will supply free spare parts 24 hours a day through international professional express as well as lifetime technical support with 24-hour response from engineers. (All services will be delivered to the customer within 5 days by Intl courier). Contact us to establish positive business relations with new and existing customers.

Our products are extensively used to make beverage and other packaging equipment due to their extensive selection, quality, low cost and bottle filling plant. We design bottles, labels as well as factory drawings. We will keep you updated of the production schedule during the production process. We will customise the machine to your specific requirements for power, material as well as the type of filling bottle sizes, etc. Visit the factories of our reference projects across the globe if you get permission from the customers.