You might even fill your bottle with delicious homemade drinks, take a long sip of freshly squeezed lemonades or apple ciders! It can be a lot of fun! So are you starting that small business and filling and capping out those shampoo or maybe hot sauce bottles for your side hustle? While on the contrary, when it comes to your bottling requirement Bottle filler and capper can automate that work in much easier way then manual.

Bottle filler and capper — The best thing about this unit is that it allows users fill their bottles accurately, while also ensuring perfect caps for each bottle. Therefore, every bottle can contain the same amount of liquid — and still cap off perfectly flush. It is a very good thing to be honest as it assures the quality of everything. Whether you are making some for yourself or selling any on, they need to be as delicious tasting.

Bottle filler and capper; bottle filling & sealing machine helps to fill the bottles within few minutes only so reduces a time. This little guy would be just perfect to fill and cap a big lot of bottles all at once. Cleanses and fills Siphon bottles at once, this will save your time very much than fill in one bottle per 1. It is great for people who have lots of bottles to fill or if they will be going through many products in quick succession as part of their business.

One more useful feature of bottle filler and capper that we often get to use is its adjustable setting. As you build it up, this part is VERY customizable so that works how YOU want! You can set the speed of how fast bottles are filled and capped, choose a pour volume per bottle as well chose which sizes of Bottles you have. Ultimately, this customizability can really be of benefit to you if your product is any different and needs special care while being filled up.

I would say a bottle filler and capper are the simplest to clean up as well. In its place it is very important to maintain anything e. h cold drinks sparkling. Easy to clean with soap and water — You need a good quality bottle filler that is easy for you to maintain. For one, they are all removeable which makes for easy cleaning if you can simply detach them by piece. Certain top-end models may get an additional coating of some kind to keep the germs or bacteria away and that is a bonus always.

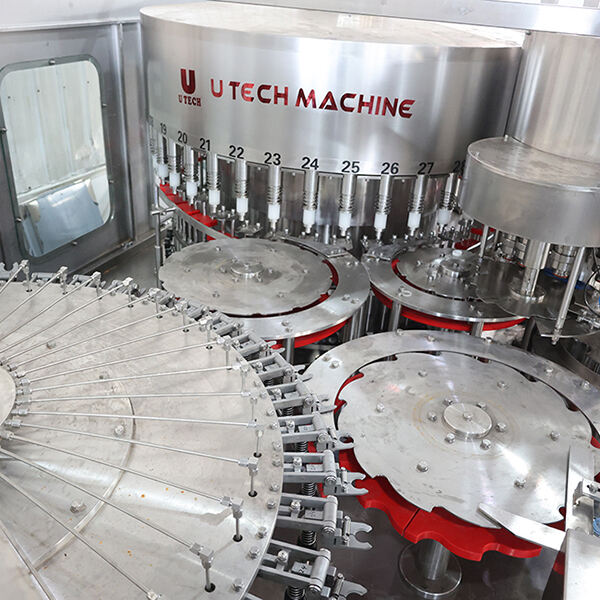

With a wide range and bottle filler and capper, as well as reasonable prices, and fashionable designs Our products are widely utilized in beverage and other packaging equipment. We are able to design bottles, labels or factory drawings. We will keep you updated of the timetable for production during the production process. We will customise the machine to meet your requirements for power, material as well as the type of filling bottle sizes, etc. We have reference project in most countries and can take you to their factories when we obtain permission from the customer.

bottle filler and capper create machine parts with a CNC machine. We are certified by CE, TUV, ISO9001 certification. We are able to provide top-quality services for our customers, starting including plant layout production equipment, layout and line design to training for operators and the best after-sales support. Our products are recognized as reliable by the users and are able to adapt to ever-changing economic and social needs. Today, our products are sold to more than twenty countries and regions that include South America, Middle East, Southeast Asia, Russia as well as the Commonwealth of the Independent States, Western Asia and South Africa.

bottle filler and capper a beverage filling machine manufacturer and packaging business with a talented technical team and well-equipped test facilities. We provide liquid filling equipment for tea, water, carbonated beverages, alcohol, and protein-rich drinks made from plant.), barreled filling line (: 1-5 gallon) water treatment machines, labeling packing machines, semi-automatic /full automatic PET bottle blowing machines, and injection molding machines, extrusion blow molding machines (PP/PE/PVC/PETG/PC) and accessories for automation: leak tester machines, bottle bag packing machines, conveyor belts.

We will provide your machine on the scheduled date. Following delivery of the product, we'll give 2 years of complimentary spare parts as well as lifetime support. We'll provide spare parts within 24 hours through international professional express as well as all-year technical support with bottle filler and capper from engineers. (All services are delivered to customer in 5 days with Intl courier). We are open to new and returning customers from all types of industries to reach us to discuss future business relations and mutual success!