Ever wonder how your favorite drink got in that bottle? It's really interesting! How does that happen — an automated bottling line is one method. This machine can help businesses with filling, capping and labeling bottles fast and in an easy way. This makes the process of bottling much quicker that if people did everything manually.

This incredible technology allows companies to save time and money. It can fill each bottle 30 times faster with far less common error than having workers do it all by hand. Since the machines are designed to work side by side, a bottle that's filled slides on down to get capped and labeled (or whatever the nest machine in line does with it) until voila- you've got boxes ready for packing.

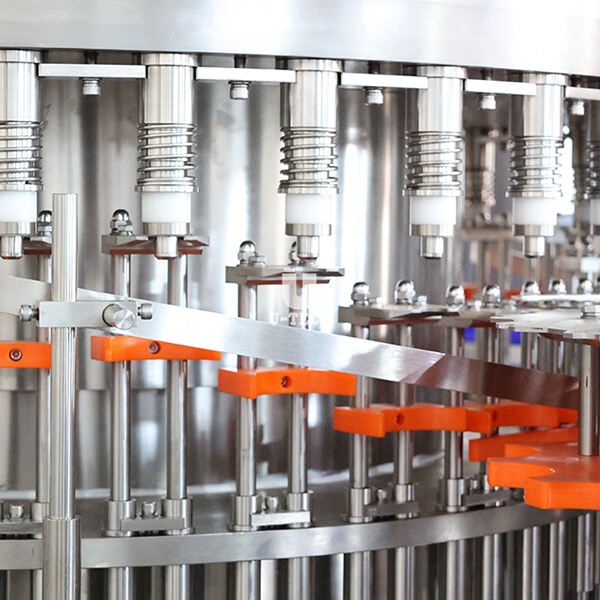

To automate this bottling line, the bottles must first be filled. The machines bottle the liquid ensuring that all bottles are being filled with equal amount. This is essential as customers expect to get the same amount of drink in each bottle they buy. So if a bottle has less than another it can really upsetting for customers.

Then after the bottle-girl are filled they will be sent to the capping machine. In it an automatic capping machine places a tighter lid or cap and ensures nothing should spill out. With that said, the drink also needs to be stored well and fresh. If the cap does not seat down well, then you would have a leak on your hands and we cannot have that!

It is through people like him that companies move faster and make fewer errors by transitioning skin care from hand poured in small batches, to be produced on an automated bottling line— allowing them to create thousands of bottles. Well because the machines do exactly same work every time, then less errors happen. It results in less waste and more drinks sold. They win, and you get to share fun content with your audience.

It also decreases the error margin of mistakes you commit. Bottles are human filled, capped and labeled. But even machines do the work, there is a low chance of mistakes so that they are highly effective but less than other methods simply making them costly as well. It assist companies to be more successful and productive.

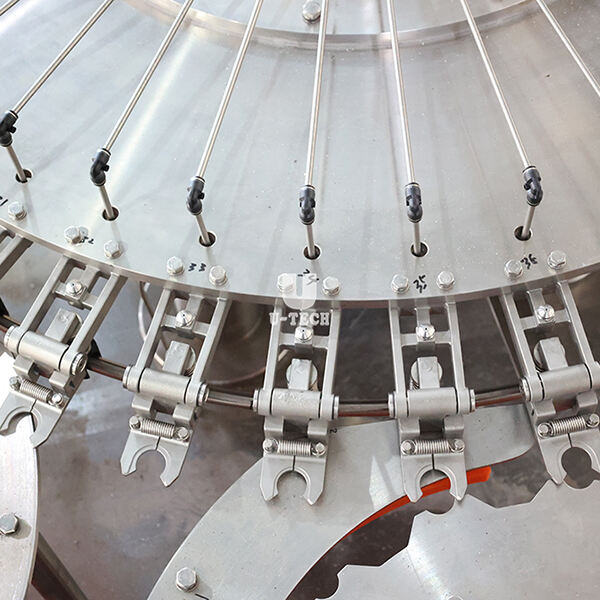

When it comes to bottling lines automated equipment, you actually have a number of different options from which to choose. There are even machines that can fill, cap and label bottles all within a single system. Some models are even designed to work with specific bottle or drink types, meaning you can choose the best machine for your needs.

The automated bottling line will be delivered on time to the time frame agreed upon by both parties. We will give 2 years spare parts free of charge, and lifetime support after the product is delivered. We will supply free spare parts 24 hours a day through international professional express as well as lifetime technical support with 24-hour response from engineers. (All services will be delivered to the customer within 5 days by Intl courier). Contact us to establish positive business relations with new and existing customers.

With a wide range, good quality, reasonable costs and attractive designs Our products are widely utilized in automated bottling line and other packing equipment. We design bottles, labels as well as factory drawings. We will keep you updated of the timetable for production during the process of production. We will customise the machine to your specific requirements such as material, power and type of filling bottle styles, etc. You can visit the factories of our projects as reference across the globe if you are granted permission by the customers.

We make automated bottling line by CNC machine. We are certified by CE TUV, CE, ISO9001 certification. We offer the best service to our customers, ranging from layout of the plant manufacturing equipment and production line setup to operator training and best after-sales service. Our products are admired and trusted by users and are able to meet ever-changing economic and social needs. Our products are currently exported to more than twenty countries including South America and the Middle East. They also export to Southeast Asia, Russia and the Commonwealth of Independent States.

Zhangjiagang U Tech Machine Co., Ltd., a manufacturer of beverage filling machines and packaging company with a seasoned automated bottling line as well as well-equipped test facilities. Our products include: liquid filling equipment (water and fruit juice/tea, carbonated drink, oil alcohol, plant protein drink, etc.), barreled filling line (: 1-5 gallon) water treatment machines, labeling packing machines, semi-automatic /full automatic PET bottle blowing machines, and injection molding machines, extrusion blow molding machines (PP/PE/PVC/PETG/PC) and accessories for automation: leak tester machines, bottle bag packing machines, conveyor belts.