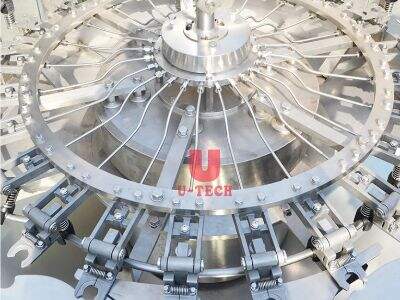

Хотите узнать несколько полезных советов, как сэкономить в процессе производства шампуня? Отличные новости, компания U Tech предлагает именно то, что вам нужно. Наше автоматическое оборудование для розлива шампуня позволяет сэкономить различными способами. Давайте узнаем, как эти машины могут помочь вашему бизнесу?

Оптимизированный процесс снижает затраты на рабочую силу

Одной из самых значительных статей экономии, которую вы можете достичь с помощью автоматической машины для розлива шампуня, является экономия на рабочей силе. Если вы используете устаревший метод розлива, вам потребуется как минимум два человека для заполнения бочек. Однако благодаря автоматическим машинам один-два сотрудника могут управлять оборудованием и следить за процессом. Это позволит сократить расходы на рабочую силу и перенаправить эти ресурсы в другие сферы вашего бизнеса.

Точное дозирование минимизирует отходы продукции

При ручном наполнении бутылок шампунь может легко проливаться и тратиться впустую. Со временем это накапливается и может обходиться вашему бизнесу довольно дорого. В сравнении с этим, машины для розлива программируются таким образом, чтобы наполнять каждую бутылку до миллилитра. Это не только снижает объем отходов продукции, но и гарантирует, что все бутылки наполняются одинаково каждый раз. Сократите отходы, увеличьте прибыль и повысьте эффективность.

Эффективность — ключ к высокой производительности и сокращению простоев

Еще одно важное преимущество таких автоматизированных машины для розлива шампуня заключается в том, что они могут повысить эффективность вашей производственной линии. Эти машины спроектированы так, чтобы быть быстрыми, эффективными и выполнять работу быстро, чтобы вы могли наполнять больше бутылок за короткое время. Это также приводит к повышению эффективности, что, в свою очередь, позволяет производить больше и лучше, чтобы удовлетворять потребности ваших клиентов. Помимо этого, автоматизированные машины имеют меньшую вероятность поломки и требуют меньше времени простоя для обслуживания, что приводит к еще большему объему производства.

Обслуживание и ремонт автоматизированных систем происходят реже

Традиционные системы розлива требуют значительных трудозатрат и дорогостоящего обслуживания. От планового технического обслуживания до непредвиденного ремонта, затраты могут быть значительными. В отличие от этого, машины для розлива шампуня являются автоматическими машинами, они прочные и требуют минимального обслуживания. Это позволяет тратить меньше времени и денег на поддержание площадки и больше времени на развитие бизнеса. Покупка такого оборудования гарантированно сэкономит вам значительную сумму денег в долгосрочной перспективе, а чтобы избежать проблем, следует инвестировать в автоматические системы.

Снижение вероятности человеческой ошибки позволяет экономить деньги со временем

Одним из самых значительных преимуществ применения автоматических машины для розлива шампуня заключается в том, что потенциал человеческой ошибки минимален. Если сотрудники самостоятельно наполняют бутылки, всегда существует вероятность ошибки, которая может привести к дорогостоящим последствиям. Переполнение бутылок и неправильная маркировка продукции могут привести к значительному расходу ресурсов и потенциально повредить репутации вашего бренда. Оборудование автоматизации предварительно настроено так, чтобы точно наполнять бутылки каждый раз, что снижает вероятность ошибок. Несмотря на первоначальные расходы, если вы экономите деньги благодаря автоматизированным системам, вы будете рады, что выбрали не самый дешевый вариант, и не будете сожалеть о решении, принятом на производственной линии.

Table of Contents

- Оптимизированный процесс снижает затраты на рабочую силу

- Точное дозирование минимизирует отходы продукции

- Эффективность — ключ к высокой производительности и сокращению простоев

- Обслуживание и ремонт автоматизированных систем происходят реже

- Снижение вероятности человеческой ошибки позволяет экономить деньги со временем