Gāzētos dzērienus ikdienā dzer daži cilvēki. Vai jūs kadām esat brīnījušies, kā tiek izveidoti šie burbuļojošie bezalkoholiskie dzērieni? Kā tiek gatavoti gāzētie dzērieni Apskatīsim, kā tiek gatavoti gāzētie dzērieni.

Visa jautrība notiek gāzēto dzērienu ražošanas līnijā. Tā ir līdzīga vienai lielai virtuvei, kur dzērienus ražo lielos apjomos. Mūsu uzņēmumā U Tech mums ir paredzētu ražošanas vienību, kas ražo mūsu gardos gāzētos dzērienus.

1. solis: Lai izgatavotu gāzētos dzērienus, mēs sākam maisīšanas telpā ar ūdeni, cukuru un garšu lielā tvertnē. To silda, lai viss varētu sajaukties kopā. Tad mēs iepumpējam oglekļa dioksīda gāzi, lai tai piešķirtu burbuļošanu. Tieši tā tiek izveidoti burbuļi limonādē/gāzētajos dzērienos!

Kad dzēriena maisījums ir gatavs, to iepilda pudelēs vai kārbās uz ražošanas līnijas. Un šīs pudeles vai kārbas tiek cieši noslēgtas, lai burbuļi paliktu iekšā. Tad mēs uzlīmējam etiķetes uz šīm pudelēm vai kārbām, lai tās izskatītos labi un būtu gatavas pārdošanai veikalos.

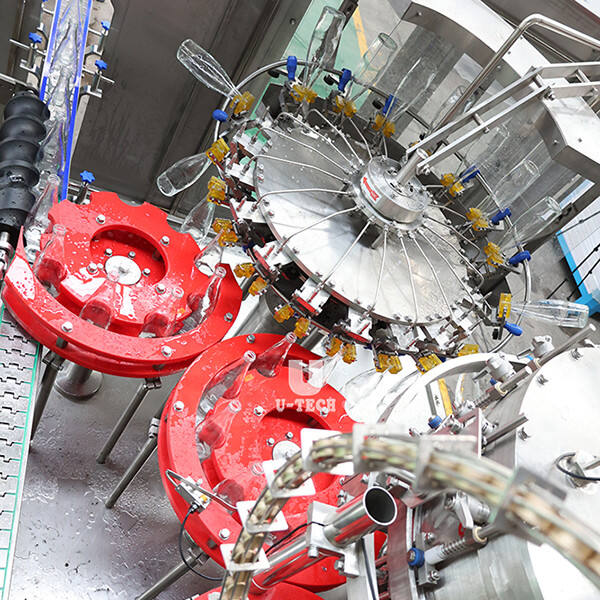

Mūsu ražošanas līnijā ir īpašas mašīnas, kas palīdz ražot dzērienus. Ir mašīna, kas pudeles vai kārbas piepilda ar dzēriena maisījumu, mašīna, kas tās noslēdz, etiķetēšanas mašīna, kas pievieno pēdējās detaļas. Šīs mašīnas visas strādā kopā, lai ražotu ideālu gāzētu dzērienu.

Gāzētam dzērienam mēs sākam ar labākajām sastāvdaļām, kādas vien varam atrast — piemēram, cukuru un garšu. Mēs tās sajaucam, pievienojam ūdeni un sildām maisījumu. Pēc piesātināšanas ar oglekļa dioksīda gāzi, dzēriens tieši uz ražošanas līnijas tiek iepildīts pudelēs vai kārbās. Beigās mēs pievienojam etiķetes, un dzērieni ir gatavi visiem!

Mēs piegādāsim mašīnu laikā, saskaņā ar datumu, ko vienojušies par gāzēto dzērienu ražošanas līniju. Mēs nodrošināsim 2 gadus bezmaksas rezerves daļas un atbalstu visu mūžu, sākot no brīža, kad produkts tiek piegādāts. Mēs piedāvāsim bezmaksas rezerves daļas 24 stundu laikā starptautiski ar profesionālu eksprespiegādi un tehnisko atbalstu visu mūžu, ar inženieru atbildi 24 stundu laikā. (Visas pakalpojumu piegādā klientiem piecu dienu laikā, izmantojot starptautisko kurjeru). Sazinieties ar mums, lai veidotu draudzību, kas būs savstarpēji izdevīga jauniem un esošajiem klientiem.

gāzēto dzērienu ražošanas līnijas izveides mašīnas detaļas ar CNC mašīnu. Mēs esam sertificēti saskaņā ar CE, TUV, ISO9001 standartiem. Mēs varam nodrošināt augstākās kvalitātes pakalpojumus saviem klientiem, ieskaitot rūpnīcas izkārtojuma ražošanas aprīkojumu, izkārtojuma un līnijas projektēšanu, operatoru apmācību un labāko pēcpārdošanas atbalstu. Mūsu produkti lietotājiem tiek atzīti par uzticamiem un spēj pielāgoties pastāvīgi mainīgajām ekonomiskajām un sociālajām vajadzībām. Šodien mūsu produkti tiek pārdoti vairāk nekā divdesmit valstīs un reģionos, tostarp Dienvidamerikā, Tuvo Austrumos, Dienvidaustrumāzijā, Krievijā, kā arī Neatkarīgo Valstu Sadraudzē, Rietumāzijā un Dienvidāfrikā.

Ar gāzētās dzērienu ražošanas līniju, augstu kvalitāti, saprātīgām cenām un modes dizainu. Mūsu produkti plaši tiek izmantoti dzērienu un citās iepakojuma iekārtās. Mēs varam palīdzēt ar rūpnīcas rasējumu, pudeļu etiķešu u.c. dizaina izstrādi. Ražošanas procesā mēs jūs informēsim par ražošanas grafiku. Mēs varam pielāgot mašīnu atbilstoši jūsu uzņēmuma prasībām, piemēram, materiālam, jaudai, pildīšanas veidam, pudeļu veidiem utt. Jūs varat apmeklēt mūsu projekta atsauču rūpnīcas daudzās valstīs, ja saņemsiet atļauju no klientiem.

Zhangjiagang U Tech Machine Co., Ltd., dzērienu pildīšanas aprīkojuma ražotājs un iepakošanas uzņēmums ar kompetentu tehnisko komandu un labi aprīkotām testēšanas iekārtām. Mēs piedāvājam šķidruma pildīšanas sistēmas ūdenim, tējai, gāzētiem dzērieniem, alkoholam, eļļai un augu olbaltumdzērieniem, ūdens apstrādes mašīnas (5 galonu) pudeļu pildīšanas līnijām, gāzētu dzērienu ražošanas līnijas, pusautomātiskas/pilnībā automātiskas PET pudeļu pūtējiekārtas, injekcijas formēšanas mašīnas, ekstrūzijas pūtējformēšanas mašīnas (PP/PE/PVC/PETG/PC) un automātizācijas piederumi: noplūdes detektora mašīnas, pudeļu iepakošanas mašīnas maisos, transportierlentes.