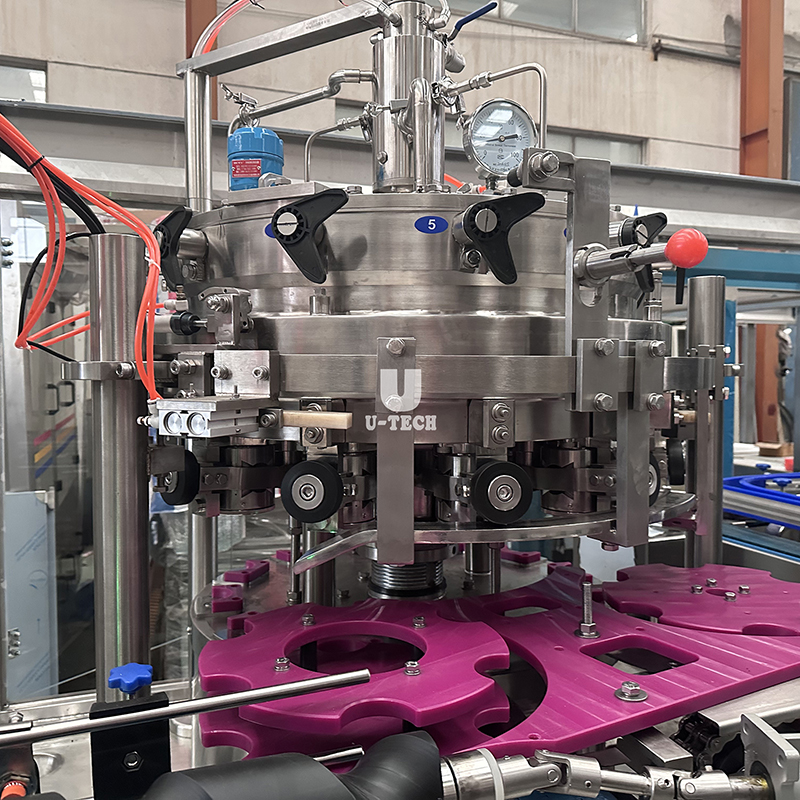

Vous vous êtes déjà demandé comment vos boissons ou collations préférées sont emballées de manière aussi efficace ? C'est vraiment fascinant. Même les machines de remplissage et de scellage monobloc effectuent ce travail spécial dont vous pourriez ignorer l'existence. Cette U Tech machines de remplissage et de bouchonage est en fonctionnement pour produire des conteneurs remplis d'aliments ou de boissons avec des joints hermétiques. Ce scellage est extrêmement important afin que ces produits puissent être livrés aux magasins sans aucun problème.

Avez-vous déjà entendu ce que signifie hermétique ? C'est un mot intéressant. Hermétique - Aucun air ne peut entrer ni sortir du contenant. De telles mesures sont extrêmement importantes pour préserver la durée de vie de nos aliments. Pourquoi ? L'oxygène pourrait être responsable de la détérioration des aliments ou les faire pourrir rapidement s'il entre en contact avec l'air. Personne ne veut manger des aliments gâtés, n'est-ce pas ? Une machine à remplissage et bouchage monobloc garantit des contenants scellés hermétiquement. Cela aide à ce que nos aliments durent plus longtemps, afin que ceux qui aiment les snacks et boissons savoureux en aient toujours sous la main.

Vous connaissez ce mot : efficacité ? Le mot est long mais sa signification ici est simple ! L'efficacité, c'est bien faire les choses et s'assurer que rien ne soit gaspillé. La machine de remplissage et de bouchage monobloc est très productive car elle peut remplir de nombreux contenants très rapidement. C'est excellent pour les usines, car la technologie U Tech machines de remplissage et de bouchonage peut produire plus de produit en moins de temps. Cela signifie que nous recevons plus de nos collations et boissons préférées beaucoup plus vite lorsque les usines fonctionnent rapidement et efficacement. Finalement, ces machines nous aident à avoir plus de délicieuses bonnes choses dans nos réfrigérateurs et congélateurs.

Avez-vous déjà réfléchi au coût de l'emballage des aliments ? Cela peut en réalité être assez élevé. La bonne nouvelle cependant est que la machine de remplissage et de bouchage monobloc économise beaucoup d'argent car elle fonctionne comme plusieurs machines en une seule. Cela garantit également que les usines n'ont pas besoin de dépenser plus d'argent pour acheter plusieurs machines ou embaucher beaucoup d'ouvriers pour une seule tâche. Cela aide ensuite à maintenir les prix de nos produits préférés abordables alors que ces mêmes usines réduisent leurs coûts d'emballage. Cela signifie que nous pouvons acheter plus de nos articles convoités à un prix raisonnable.

Les résultats de la machine de remplissage et de scellage monobloc sont utilisés de plus en plus dans les usines. Elle peut sceller tous types d'aliments à l'avance et est très rapide, ce qui vous fait économiser de l'argent. Avec autant d'avantages, il est clair pourquoi ces machines sont si recherchées. Et elles sont également importantes car elles nous permettent de consommer nos produits préférés frais et délicieux. À chaque fois que vous buvez ou mangez depuis une canette/une bouteille, souvenez-vous qu'il existe des machines fantastiques comme U Tech. machine de remplissage de bouteilles monobloc qui intervient à toutes les étapes pour aider à emballer robustement toutes ces choses.

Zhangjiagang U Tech Machine Co., Ltd., un fabricant de machines de remplissage de boissons et une entreprise d'emballage disposant d'une équipe technique qualifiée et d'installations d'essai bien équipées. Nous fournissons des machines de remplissage liquide pour le thé, l'eau, les boissons gazeuses, l'alcool, l'huile et les boissons à base de protéines végétales, des machines monoblocs de remplissage et de bouchage (: 1-5 gallons), des machines de traitement de l'eau, des machines d'étiquetage et d'emballage, des machines de soufflage de bouteilles PET semi-automatiques / entièrement automatiques, des machines de moulage par injection, des machines de moulage par extrusion-soufflage (PP/PE/PVC/PETG/PC) ainsi que des accessoires pour l'automatisation : machines de détection de fuites, machines d'emballage de bouteilles en sac, convoyeurs.

La machine de remplissage et de bouchage Monobloc sera livrée à temps dans le délai convenu par les deux parties. Nous offrirons gratuitement des pièces détachées pendant 2 ans, ainsi qu'un support à vie après la livraison du produit. Nous fournirons des pièces détachées gratuites 24 heures sur 24 via un transporteur express international professionnel, ainsi qu’un support technique à vie avec une réponse d'ingénieurs sous 24 heures. (Tous les services seront acheminés au client dans un délai de 5 jours par courrier international). Contactez-nous pour établir des relations commerciales positives avec les clients nouveaux et existants.

Avec une large gamme, une bonne qualité, des prix raisonnables et des designs tendance, nos produits sont des machines monobloc de remplissage et de bouchage pour l'industrie des boissons et d'autres équipements d'emballage. Nous pouvons vous aider à concevoir les plans d'usine, les étiquettes des bouteilles, les bouteilles, etc. Au cours de la production des machines, nous adapterons votre planning de production en temps voulu. Nous pouvons modifier la machine pour répondre à vos exigences en matière de matériau, de puissance ainsi qu'en fonction du type et des dimensions des bouteilles à remplir, etc. Nous disposons de projets de référence dans plusieurs pays et pouvons vous emmener dans leurs usines dès lors que le client aura donné son accord.

Nous fabriquons des pièces de machine avec des machines-outils CNC. Nous sommes certifiés par la machine de remplissage et de bouchage Monoblock, TUV et ISO9001. De la conception des usines à la fabrication d'équipements et à la mise en place de chaînes de production, nous sommes en mesure d'offrir le meilleur service à nos clients. Nos produits sont bien connus et largement fiables, et peuvent répondre aux besoins en constante évolution dans les conditions socio-économiques. Nos produits sont vendus dans plus de 20 pays, y compris l'Amérique du Sud et le Moyen-Orient. Ils sont également exportés en Asie du Sud-Est, en Russie et dans les États indépendants.