If you have ever looked at a bottle of spirits and asked yourself how this lovely liquid gets from the distillery to your favorite store, then pull up your bar stool next to me. There is a unique process involved in making the spirits ready for being sold, and that has been named as the Spirits bottling line.

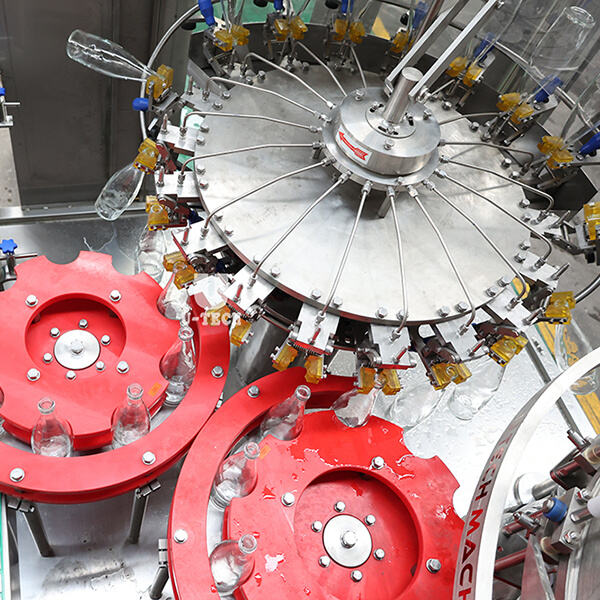

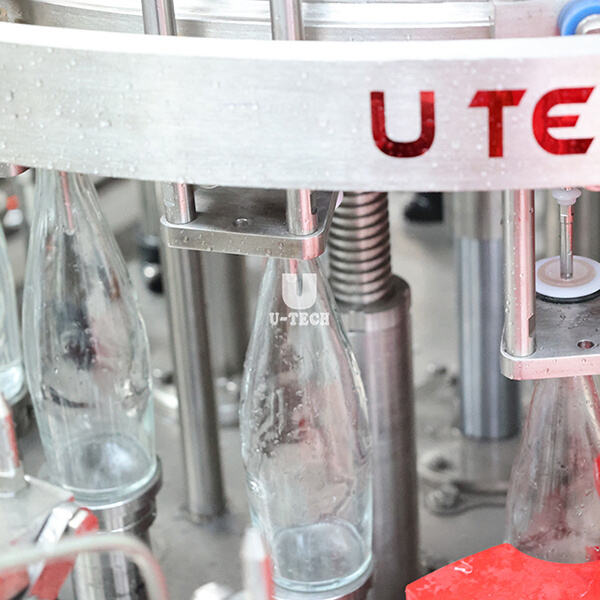

The bottling line for spirits is a special place. Just all the area where life happens to ensure that when those spirits get out, they are indeed top-notch. They employ great machines which can fill as many as 600 bottles in a minute! That’s really fast! These machines help ensure that every bottle of has the same amount of spirit in it. This is crucial since it guarantees that the taste stay constant, no matter how many bottles they sell. That way, when you crack open a bottle, you can count on that age-old flavor to delight your senses.

After being filled with spirits the bottles needed labels. Labels tell your customers what is inside the bottle and are critical. The spirits bottling line is even harder at work, getting every label on correctly and without errors. A good label can make someone choose to buy the bottle so it is in their interest for everything to be just right and they take all time you allow them. They use special devices that help make sure that every label is straight and correctly stuck on the bottle. This meticulous work makes the bottles presentable and definitely suitable for an upscale market.

Labeled bottles are then packed. There are many ways to pack popcorn, such as a plain cardboard box or an elegant presentation case. Our spirits bottling line loves to remind everyone that a spirit tastes better when it looks good. The bottling will be done smoothly and carefully to allow no damage on the bottle or label during transit or stay at shelves. Fantastic packaging not only safeguards the spirits, but also makes these even more attractive to consumers.

The certified spirits bottling line is equally fast (as determined by production requirements) and incredibly low yield-like efficient. What this actually translates to in more practical terms, is that the machines are prepared and programmed in a way for them to arrive quickly at what they do very well while also minimizing unnecessary overuse. For example, all residual spirits that may remain are sent back to the distillery and the waste produced (empty boxes or labels) is properly disposed. Which is better for the environment and cheaper to bottle.

With a variety of products with good quality, competitive pricing and trendy designs our products are extensively employed in beverage and other packaging equipment. We can design bottles, labels, factory drawings, etc. When the machine is in production we will make changes to the production schedule for you on the appropriate date. We will customise the machine to meet your specifications such as material, power and filling type, bottles, and so on. We have reference projects in a variety of countries and we can show you their facilities if we have the spirits bottling line.

Zhangjiagang U Tech Machine Co., Ltd. is a manufacturer of beverages filling equipment and packing with well-equipped testing facilities as well as a strong technical force. Our products include: liquid filling equipment (water tea, fruit juice, carbonated drinks, oil, alcohol, plant protein drinks and more.), barreled filling line (: 1-5 gallon) water treatment machines, labeling packing machines, semi-automatic /full automatic spirits bottling line, and injection molding machines, extrusion blow molding machines (PP/PE/PVC/PETG/PC) and accessories for automation: leak tester machines, bottle bag packing machines, conveyor belts.

We manufacture machine components using CNC machines. We are certified by CE TUV, CE, ISO9001 certification. From the layout of the plant to the manufacturing of equipment and production line set-up, we can provide the best possible service to our clients. Our products are widely known and widely used and are able to be used to meet ever-changing economic and social requirements. Now our products are exported to more than 20 countries and regions that include South America, spirits bottling line, Southeast Asia, Russia and the Commonwealth of the Independent States, Western Asia and South Africa.

The machine will be delivered on time to the deadline agreed between both parties. We will offer 2 years free spare parts, and spirits bottling line once the product is delivered. We'll provide spare parts in 24 hours via international express professional and all-year technical support with 24 hour engineer response. (All services are delivered to customers within 5 days via Intl courier). We are happy to welcome both old and new customers from all types of industries to reach us for future business relationships and shared success!