Ever wondered how they make soda bottles? It’s quite interesting! This machine is known as the soda bottling plant series of machines, this blog discusses about these bottle filling and sealing process in a detailed way. This machine is responsible of making sure that we have our favorite sodas to drink.

A soda bottling plant machine is huge and comprises of many parts inside it. It operates on electricity which helps it functioning at its peak. Sometimes the machine is covered in buttons and switches that allow customers to make their own variety of soda, such as cola or lemon-lime-or even root beer. The conveyor belt is hands down one of this machine's nice feature. With the bottles moving on a conveyor belt, it takes only seconds to fill every bottle with soda in an organized and quick manner.

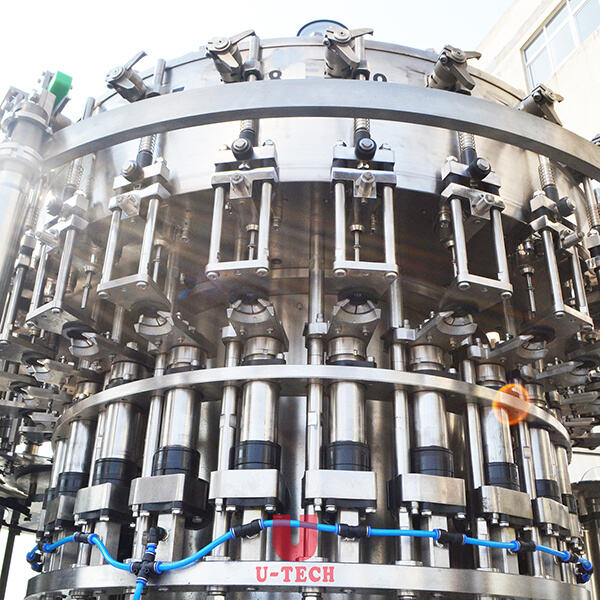

Soda machine, the one that fill drinks into bottles. It is composed of many sections which are put together to work in harmony to top up and cap the bottles accurately. Because of how important this process is, it seals in the freshness that keeps your soda fizzy. It is also important to keep the machine dust free. However, when the machine is dirty, a lot of bacteria will be created inside and as long as we drink from this soda which might have been exposed to that wet environment it means there are alot portable food for both: us human beings (i.

It is a machine on which beverages that we have become accustomed to drinking every day are prepared. They make the process of bottling cleaner, and more efficient. This wonderful machine lets companies produce enough soda for everyone to enjoy with out it this would be a very difficult task. Just think if there were shortages of soda and people had to wait in line to get some from the store right! This machine will prevent this.

The soda bottling plant has multiple steps in its production process - each one followed meticulously. The first thing that is obviously done to get sterilized water from returnable glass bottles, is the cleaning of those bottle very thoroughly so no dirt or any other residues are in them. This is vitally important to maintaining the drinkability of your soda. The sealed is fixed very tightly after soda adds to the bottles. The machine then labels the bottles. These labels let us know, for example, what kind of soda is inside and the drink-by date on that jug we so guzzled.

Finally, the bottled are filled and labeled, sent down conveyer belt for packaging into boxes to be shipped. So that they can be sent to stores for purchase.

We manufacture machine parts using a CNC machine. We are accredited by CE TUV, CE, and ISO9001. We are able to provide soda bottling plant machine for our clients, including plant layout manufacturing equipment and production line configuration to operator training and top after-sales services. Our products are well-known and trusted by consumers and are able to meet ever-changing demands in the social and economic spheres. Our products are now exported to more than 20 countries and regions which include South America, Middle East, Southeast Asia, Russia as well as the Commonwealth of the Independent States, Western Asia and South Africa.

We will deliver the machine on time according to the date agreed by both parties. Once we have delivered the product, we'll provide 2 years of free spare parts as well as lifetime support. We will ship spare parts within soda bottling plant machine using international professional express. We also offer lifetime technical support for your machine, 24 hours for engineer response (all support services will be provided for 5 days after delivery to the hands of the customer by Intl' courier). Contact us to establish positive business relations with current and new customers.

With a variety of products with good quality, soda bottling plant machine, and fashionable designs our products are extensively used in beverage as well as other packing equipment. We design bottles, labels, factory drawings, etc. We will keep you aware of the production schedule during the production process. We will design the machine according to your requirements, materials power, filling types, the kinds of the bottles and so on. You can visit the factories of our project references in many countries if you are granted permission by the customers.

Zhangjiagang U Tech Machine Co., Ltd., a manufacturer of beverage filling equipment and soda bottling plant machine, has a strong technical team and well-equipped test facilities. Our products include liquid filling machines (water or fruit juice/tea carbonated drink, oil alcohol, plant protein drink, etc), barreled filling line (: 1-5 gallon) water treatment machines, labeling packing machines, semi-automatic /full automatic PET bottle blowing machines, and injection molding machines, extrusion blow molding machines (PP/PE/PVC/PETG/PC) and accessories for automation: leak tester machines, bottle bag packing machines, conveyor belts.