Hot sauce is a unique and yummy condiment that so many people just pour on everything they eat. It spices up the taste of food making it more flavorful. As fun and exciting as making your hot sauce can be, doing it all by hand can also take a considerable amount of time and effort. Hot Sauce Bottle Filling Machine They are made with specific machines that able to fill hot sauce bottles, so you will not have any problems related to this recurrent. In this article we will show you how these machines can save time, filling up bottles in 5 different ways and the many advantages of using them, why makers love to use Hot Sauce Filling Machines and they are used hire lot when comes producing a great volume of hot sauce.

Hot sauce bottle filling machines are highly useful for saving you time in making your own hot sauces. That can easily end up being very time consuming if you have many bottles to fill, usually my husband sits there filling each bottle by hand. But hot sauce makers can very quickly fill many bottles at once with these machines. As a result, they can produce more hot sauce in less time — an important factor for companies who manufacture and distribute hot sauces to the masses. In using these machines, makers can work faster and have the final product on their customers' table more quickly.

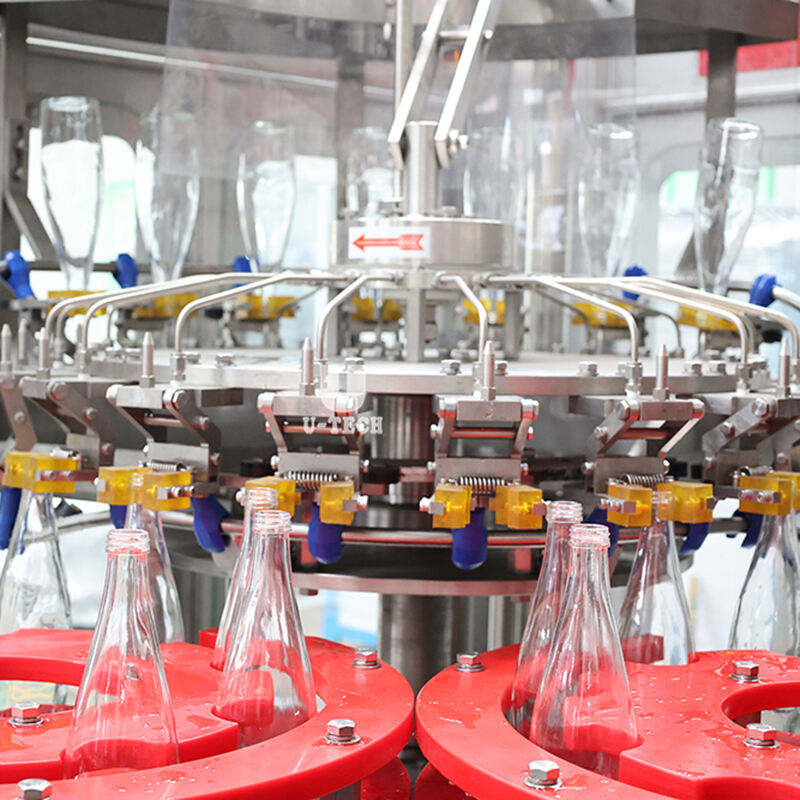

How hot sauce is BottledThere a few ways that different companies bottle the hot stuff. One of the most popular methods is Gravity Filling. This system works much like an enema, forcing the hot sauce down to fill up each bottle using gravity. This is more common with the piston filling method. Using a pumper, which is the small device pushes the hot sauce into everything so every bottle gets its necessary amount Another method of filing is with a vacuum, which removes the air inside the bottle. The hot sauce is also sucked into the bottle of this vacuum, and it can be filled very quickly.

There are for sure many good benefits to be had in using hot sauce bottle filling machines. The largest pro is that it helps save time and makes workers more productive. Speeds up filling bottles for hot sauce makers It is also used to make even distribution of hot sauce in every bottle. This uniformity is important as it ensures the hot sauce maintains a fantastic taste and keeps consumers happy. Moreover, these machines are modifiable for diverse bottle sizes and unusual shapes to cater producers with assorted forms of bottles that make hot sauce.

There are a number of reasons that hot sauce companies choose to use filling machines specifically. One reason is that these machines simplify and accelerate the manufacturing process. Hot sauce, for example needs a consistent level of quality to rely on in every bottle. And filling machines provide such consistency, which is key to maintaining satisfied customers. Moreover, these machines help hot sauce makers save time and resources. This should allow them to concentrate on other more critical areas of their business – selling the hot sauce, marketing it or experimenting with new appealing flavors that customers would probably like.

Hot sauce bottle filling machines are therefore particularly useful if you need to make a large quantity of hot sauce. Manually filling bottles is often really time consuming and labour intensive. These machines allow people making hot sauce to produce a tremendous amount of the spicy, flavorful condiment in little time and with exceptional ease. Especially during holidays and events where a lot of people are going to be buying hot sauce this is essential. Machines also reduce the chances of waste and errors. This will save hot sauce makers money by providing them with a more successful business.

With a wide range and good quality, as well as reasonable pricing and hot sauce bottle filling machine Our products are widely utilized in beverage and other packaging equipment. We can assist you in designing labels for bottles, factory drawings labels, and bottles. We will keep you aware of the production schedule during the process of production. We can customize the machine to meet your requirements for power, material and type of filling bottle sizes, etc. You can visit the manufacturing facilities of our projects as reference in a variety of countries, provided you are granted permission by the customers.

We manufacture machine parts using a CNC machine. We are accredited by CE TUV, CE, and ISO9001. We are able to provide hot sauce bottle filling machine for our clients, including plant layout manufacturing equipment and production line configuration to operator training and top after-sales services. Our products are well-known and trusted by consumers and are able to meet ever-changing demands in the social and economic spheres. Our products are now exported to more than 20 countries and regions which include South America, Middle East, Southeast Asia, Russia as well as the Commonwealth of the Independent States, Western Asia and South Africa.

Zhangjiagang U Tech Machine Co., Ltd., a manufacturer of beverage filling machines and packaging business with a talented team of engineers and well-equipped testing facilities. Our products include liquid filling equipment (water and fruit juice/tea, carbonated drink, oil alcohol, plant protein drink, etc.), barreled filling line (: 1-5 gallon) hot sauce bottle filling machine, labeling packing machines, semi-automatic /full automatic PET bottle blowing machines, and injection molding machines, extrusion blow molding machines (PP/PE/PVC/PETG/PC) and accessories for automation: leak tester machines, bottle bag packing machines, conveyor belts.

The hot sauce bottle filling machine will be delivered on time to the time frame agreed upon by both parties. We will give 2 years spare parts free of charge, and lifetime support after the product is delivered. We will supply free spare parts 24 hours a day through international professional express as well as lifetime technical support with 24-hour response from engineers. (All services will be delivered to the customer within 5 days by Intl courier). Contact us to establish positive business relations with new and existing customers.