Carbonated beverages are being consumed daily by some people. Did you ever wonder how these bubbly soft drinks are created? How Carbonated Drinks Are Made Let's see how carbonated drinks are made.

The fun is all at the carbonated drink production line. It’s like one big kitchen for making drinks in bulk. At our company U Tech, we have dedicated production unit for producing our delicious aerated beverages.

Step 1: To create carbonated beverages, we begin in the mixing room with water, sugar and flavor in a large tank. This is heated up so everything can melt together. Then, we pump in carbon dioxide gas to give it its fizz. This is the way that the bubbles in soda/fizzy drinks are made!

With the beverage mix done, it is can or bottled on the production line. And these bottles or cans are sealed tight so the fizz stays contained. Then we label those bottles or cans, so they look nice and are ready to be sold in stores.

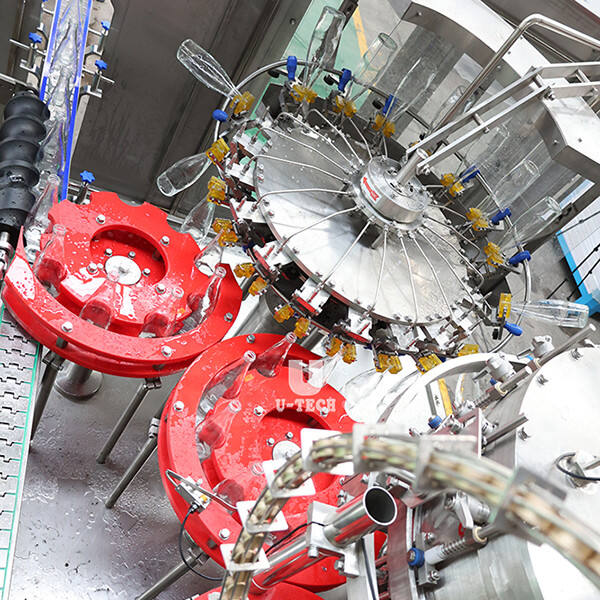

On our production line, we have special machines that help to produce the drinks. There’s a machine that fills bottles or cans with the drink mixture, a machine that seals them, a labeling machine that puts on the final touches. These machines all work together to produce the ideal carbonated beverage.

For a carbonated beverage, we start with the finest ingredients we can find — say, sugar and flavor. We mix these and add water and heat the mixture. After infusion with carbon dioxide gas, the drink is bottled or canned directly on the production line. Finally, we add labels and the drinks are ready for all!

We will deliver the machine at a time, according to the date agreed by carbonated drink production line. We will give 2 years free spare parts and lifetime support following the time the product is delivered. We will offer free spare parts within 24 hours via international professional express and lifetime technical support, with 24-hour response from engineers. (All services are delivered to customers within five days using Intl courier). Contact us to build friendships that are mutually beneficial to new and existing customers.

carbonated drink production line create machine parts with a CNC machine. We are certified by CE, TUV, ISO9001 certification. We are able to provide top-quality services for our customers, starting including plant layout production equipment, layout and line design to training for operators and the best after-sales support. Our products are recognized as reliable by the users and are able to adapt to ever-changing economic and social needs. Today, our products are sold to more than twenty countries and regions that include South America, Middle East, Southeast Asia, Russia as well as the Commonwealth of the Independent States, Western Asia and South Africa.

With a carbonated drink production line, good quality, reasonable prices, and fashionable designs Our products are widely utilized in beverage and other packaging equipment. We are able to assist you with the design of factory drawing, bottles labels, etc. We will inform you about the schedule of production during the process of production. We can customize the machine according to the requirements of your company, such as material, power, filling type, the kinds of the bottles and etc. You can visit the factories of our project references in many countries if you get permission from the customers.

Zhangjiagang U Tech Machine Co., Ltd., a manufacturer of beverage filling equipment and packaging firm with a talented technical team and well-equipped testing facilities. We offer liquid filling systems for water, tea, carbonated drinks, alcohol, oil and plant protein drinks.), barreled filling line (: 1-5 gallon) water treatment machines, carbonated drink production line, semi-automatic /full automatic PET bottle blowing machines, and injection molding machines, extrusion blow molding machines (PP/PE/PVC/PETG/PC) and accessories for automation: leak tester machines, bottle bag packing machines, conveyor belts.