Crumbling the notion of Restaurant as an ideal starter pack in weight lifting (since no restaurant gives everything for free, right?) If you have — and odds are that, at one of the adjacent movie theaters or grocery store chain locations in your vicinity, you have done so many times over- it is likely on account a machine doing some variation thereof just filling up a cup with soda or something cold. The soda filling machine is an automatic one It is extremely hand as with the press of flowrate it could pour a perfect drink into any glass within seconds. These machines are used in some businesses, such as certain restaurants and convenience stores, to automatically fill a drink. Long story short: a machine is able to fill each cup faster than it could be filled by hand and in the meantime more efficiently.

However, if you are filling the glasses by hand — 35into a glass for yourself and then more than half into other servings. This is typically quite messy and the drinks dont get consumed properly which isnt that great for business. This is where the automatic filling machine comes in; it makes this process cleaner and more efficient. Each dose of fizz put into a glass [above]The Fizzini literally dispenses the proper amount of drink, automatically stopping because you overfilled the thing. It is also spill-free so no more linking any amount of it! Not only did this save money and resources, but it also wastes additional drinks that spilled out onto the floor.

If you do have a drinks business of your own… You owe it to yourself to check out an automatic filler machine. It had you whip up more drinks in less time and cut back on your precision. This way your employees can do something else, of value and save time since they no longer need to measure cups. Such as customer work, cleaning or general help that needs doing. A good beverage filling machine can streamline and optimize the process of making a drink for all parties involved.

There are many benefits of using the type of vending machine that dispenses soft drinks over a unit with by-the-cup filling capabilities. This allows it to serve many drinks at the same time much easier, and we all know that is a good thing when events are busy. It also guarantees uniform amounts of drink in cup…there are the same amount of it n each of them, therefore every customer is content and obtains identical quality (Figure 22c). Thirdly — the more parts one has, the greater maintenance required | It is easier to clean In the end, this will save time and energy keeping the business rolling as well keeping customers happy. With even more customers an operation means that businesses can push significantly faster.

Nowadays automatic filling machines are much more sophisticated and smarter than those all-mechanical models of the past. They are extremely versatile in that they can host any soft cold drink whether it be carbonated or non-carbonated, and also hot coffee/tea whilst being compatible with a range of different cup sizes. Some machines have features in which lids are auto-capped or liquid goes directly into the mixing chamber, and some machinery dispenses syrup. These features not just supports the business but additionally provides customers what they want and to their amount.

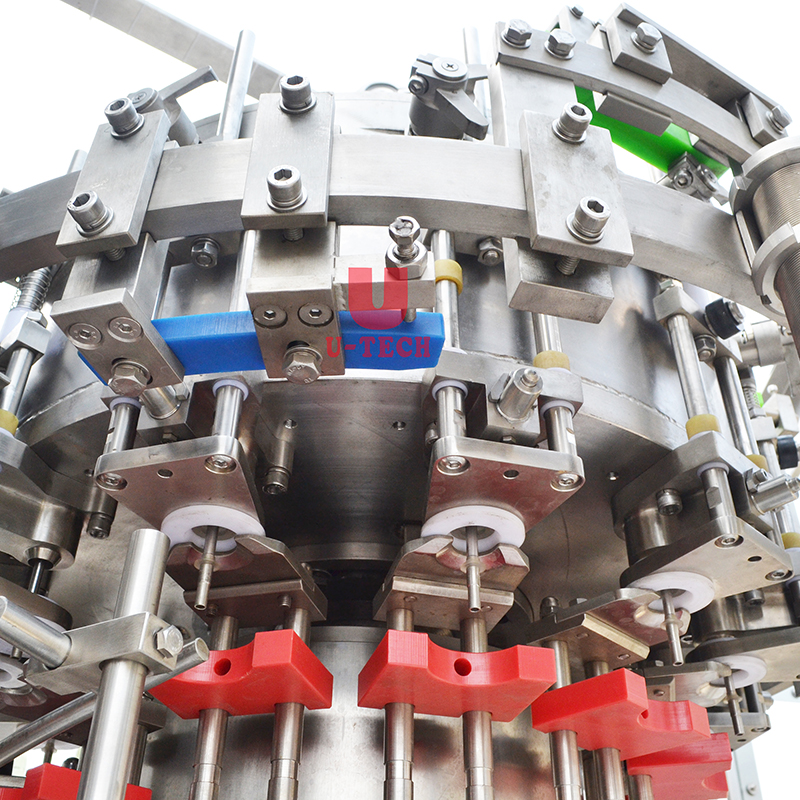

We make machine parts with CNC machines. We are certified by automatic soft drink filling machine, TUV and ISO9001. From layout of plants to the manufacturing of equipment and production line setup, we are able to offer the best service for our customers. Our products are well-known as well as widely trusted, and they can meet constantly changing needs in social and economic conditions. Our products are sold to more than 20 countries, including South America and the Middle East. They also go to Southeast Asia, Russia and the Commonwealth of Independent State.

Our products are extensively used to make beverage and other packaging equipment due to their extensive selection, quality, low cost and automatic soft drink filling machine. We design bottles, labels as well as factory drawings. We will keep you updated of the production schedule during the production process. We will customise the machine to your specific requirements for power, material as well as the type of filling bottle sizes, etc. Visit the factories of our reference projects across the globe if you get permission from the customers.

The machine will be delivered at a time as per the deadline agreed between both parties. Following delivery of the product, we'll offer 2 years of no-cost spare parts and lifetime support. We will offer free spare parts in 24 hours via automatic soft drink filling machine and lifetime technical support with 24 hour engineer response. (All services will be delivered to the customer within 5 days via Intl courier). Contact us today to establish mutually beneficial business relationships with current and new customers.

Zhangjiagang U Tech Machine Co., Ltd., a manufacturer of beverage filling equipment and automatic soft drink filling machine, has a strong technical team and well-equipped test facilities. Our products include liquid filling machines (water or fruit juice/tea carbonated drink, oil alcohol, plant protein drink, etc), barreled filling line (: 1-5 gallon) water treatment machines, labeling packing machines, semi-automatic /full automatic PET bottle blowing machines, and injection molding machines, extrusion blow molding machines (PP/PE/PVC/PETG/PC) and accessories for automation: leak tester machines, bottle bag packing machines, conveyor belts.